The Best Guide to AI and Robotics in Construction: Boosting Efficiency and Safety with Advanced Management Software

Table of Contents:

The construction industry is entering a new era, one where Artificial Intelligence (AI) and robotics are transforming how we build, manage, and execute projects. From streamlining processes to enhancing worker safety, these cutting-edge technologies have revolutionized construction management. This guide dives into the role of AI and robotics in construction, exploring the tools, techniques, and best practices that are boosting productivity and safety on job sites worldwide.

How AI and Robotics are Revolutionizing Construction

AI and robotics are no longer futuristic concepts; they are the here and now in construction. With machine learning algorithms and autonomous machinery, construction managers can streamline tasks that once took days, all while reducing errors and improving safety.

The Power of Artificial Intelligence in Construction

AI brings unmatched precision and foresight to construction projects. Machine learning algorithms analyze large amounts of project data to make better predictions, such as estimating project timelines and managing resources. With AI’s predictive analytics, contractors can minimize downtime, anticipate project risks, and optimize schedules to avoid costly delays.

AI-powered software is also helping project managers make smarter decisions by analyzing past project data. For example, AI can identify the optimal use of materials or pinpoint the best ways to allocate labor for efficiency. With real-time data insights, teams can stay one step ahead, reducing the chance of expensive mistakes and boosting productivity.

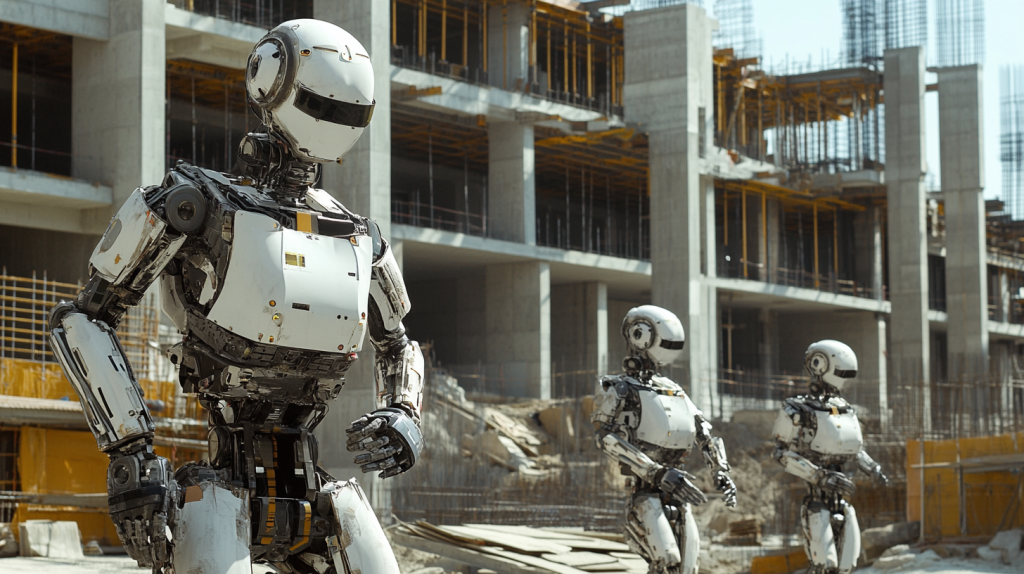

Robotics Taking Over Repetitive and Hazardous Tasks

Robots on construction sites may sound like science fiction, but they’re becoming a practical reality. Automated robots handle repetitive or hazardous tasks, such as bricklaying, welding, and demolition. By taking over these physically demanding jobs, robotics not only reduce injury risks for workers but also help projects finish faster and more accurately.

For instance, robotic bricklayers can place thousands of bricks a day, while human bricklayers may handle only a fraction of that amount. This technology doesn’t replace skilled workers but complements them, freeing them to focus on tasks that require human intuition and problem-solving.

Key Benefits of AI and Robotics in Construction

The combination of AI and robotics is proving to be a game-changer in construction. Here are the major benefits of implementing these advanced technologies on construction sites:

1. Increased Efficiency

AI and robotics streamline repetitive tasks, improve workflows, and enable better resource management. AI-driven scheduling, for instance, ensures that teams are deployed optimally, minimizing downtime and maximizing productivity.

2. Enhanced Safety

By automating hazardous tasks, robotics keep workers out of harm’s way. Additionally, AI-powered safety monitoring systems can predict potential risks and alert teams before accidents happen, creating a safer job site environment.

3. Cost Savings

With better accuracy and efficiency, construction projects experience fewer delays and reduced waste, which translates to significant cost savings. AI can optimize resource allocation and material usage, preventing costly overruns.

4. Better Quality Control

AI-driven quality control systems can analyze project data in real-time, catching potential issues before they escalate. This ensures that the final product meets the highest standards, reducing rework and improving client satisfaction.

Top Applications of AI and Robotics in Construction

AI and robotics are versatile tools with a range of applications in construction. Here’s a closer look at how these technologies are being used to transform the industry.

AI for Project Planning and Scheduling

AI-based project planning tools can analyze historical data to create optimized schedules, resource allocations, and timelines. Machine learning algorithms can predict potential project bottlenecks, allowing project managers to make adjustments in real time. This ensures that projects stay on schedule and within budget.

Autonomous Equipment and Robotics for On-Site Work

Robotics are taking on tasks that are physically demanding and often dangerous. Automated vehicles transport materials across job sites, while robotic arms handle heavy lifting and repetitive tasks. This not only reduces the physical strain on workers but also speeds up the overall construction process.

AI-Powered Drones for Site Inspection

Drones equipped with AI technology are now used for site inspections and monitoring. These drones capture high-resolution images and videos of construction sites, which AI algorithms then analyze to assess project progress, identify safety risks, and ensure compliance with building standards. This technology allows managers to inspect sites without physically being present, saving time and reducing potential safety hazards.

Predictive Maintenance with AI

AI’s predictive maintenance capabilities are helping keep construction equipment in optimal condition. By analyzing data from machinery sensors, AI can forecast when a machine is likely to fail or need maintenance, enabling proactive repairs. This reduces equipment downtime and ensures that projects run smoothly.

Robotic Exoskeletons for Worker Assistance

Robotic exoskeletons assist construction workers in lifting heavy materials or working in awkward positions for extended periods. These wearable devices enhance human strength and endurance, allowing workers to perform physically taxing tasks more easily and reducing the risk of injury.

How AI and Robotics Improve Safety on Construction Sites

Safety is a top priority in construction, and AI and robotics play a crucial role in making job sites safer for everyone. Here’s how these technologies enhance safety:

Real-Time Safety Monitoring with AI

AI-powered safety systems can monitor construction sites in real-time, using data from cameras, sensors, and IoT devices to detect potential safety hazards. For example, if a worker enters a restricted area or isn’t wearing the required PPE, the AI system can immediately alert supervisors.

Hazardous Task Automation with Robotics

Robotics can handle tasks that are risky for human workers, such as working at extreme heights, handling heavy materials, or performing demolitions. By delegating these tasks to robots, construction companies significantly reduce the risk of accidents on the job site.

Preventative Maintenance for Equipment

AI’s predictive maintenance capabilities help ensure that equipment is safe to use. By alerting operators to potential issues before they become dangerous, AI reduces the risk of equipment failure and related accidents.

Implementing AI and Robotics in Construction: Best Practices

Implementing AI and robotics in construction requires careful planning and a focus on seamless integration with existing workflows. Here are some best practices to ensure a successful adoption:

1. Assess Your Project Needs

Before investing in AI or robotics, evaluate your project needs. Determine where these technologies can add the most value, whether in safety monitoring, quality control, or task automation. This will help you choose the right tools and allocate resources effectively.

2. Start Small and Scale Up

Begin with smaller, manageable applications before committing to a full-scale rollout. For instance, you might start by using AI for scheduling and resource allocation before moving on to robotics for heavy lifting or site inspection. This approach allows you to evaluate the impact and make adjustments as needed.

3. Train Your Workforce

Investing in technology is only effective if your workforce can use it effectively. Provide training to ensure that your team understands how to operate and interact with AI and robotic systems. This will help them feel comfortable with the technology and improve overall project outcomes.

4. Partner with Experienced Providers

Working with established providers of AI and robotics for construction will make the implementation process smoother. These providers can offer support, training, and troubleshooting, ensuring that you get the most out of your investment.

Related Articles:

Best Guide to AI in Construction Project Management: How Smart Tools Are Improving Construction Site Productivity; AI

Best Guide to Geographic Information Systems (GIS) in Construction: How Location-Based Data Improves Construction Project Management

Best Guide to Smart Helmets in Construction: Enhancing Safety, Communication, and Site Efficiency

Best Construction Scheduling Software for General Contractors and Superintendents

Best Guide to Solar Farm Construction Management: Top Solar Construction Management Software for Tracking Projects, Deliveries, and Compliance

StruxHub

Experience the power of StruxHub today and witness firsthand how it can revolutionize your construction operations.

Future Trends: What’s Next for AI and Robotics in Construction?

As AI and robotics continue to evolve, the future of construction looks increasingly automated and efficient. Here are some trends to watch:

AI-Driven Predictive Analytics for Project Management

Predictive analytics will become even more accurate, allowing construction managers to make data-driven decisions that keep projects on track. Advanced AI algorithms will predict potential delays, resource shortages, and risk factors with even greater precision.

Fully Autonomous Job Sites

Imagine a job site where automated machinery and AI-driven software handle everything from scheduling to safety checks without human intervention. Fully autonomous job sites are closer than ever, with some companies already testing fully automated equipment that works around the clock.

Collaborative Robots (Cobots)

Cobots, or collaborative robots, are designed to work alongside human workers, assisting with tasks that require both human intelligence and robotic precision. These robots will increasingly become part of the construction workforce, enhancing productivity without replacing skilled labor.

AI-Powered Building Information Modeling (BIM)

AI will continue to enhance Building Information Modeling (BIM) technology, helping project managers visualize projects more accurately and make real-time adjustments. AI-enhanced BIM will enable precise project modeling that accounts for every detail, from material usage to environmental impact.

Why AI and Robotics are Essential for the Future of Construction

AI and robotics are not just trends; they are essential tools that are shaping the future of construction. By enhancing efficiency, improving safety, and reducing costs, these technologies are helping construction companies meet modern demands and stay competitive. As AI and robotics become more sophisticated, their role in construction will only continue to grow, offering exciting new possibilities for project management, safety, and overall project success.

Unlock the Full Potential of Your Construction Projects with StruxHub

StruxHub enhances efficiency and coordination across all project phases, providing a single source of truth that eliminates silos and fosters collaboration. Real-time updates, financial management tools, and seamless commvunication features ensure that all team members and stakeholders are aligned and informed, reducing the risk of errors and delays. With comprehensive solutions for document management, risk mitigation, and quality control, StruxHub maintains project integrity and safety, while mobile access and integration capabilities further enhance project flexibility and efficiency.

StruxHub’s Key Features and Benefits:

- Advanced Delivery Management: Automate and optimize your delivery schedules, ensuring materials arrive just in time, every time.

- Site Communication: Utilize georeferenced maps and instant messaging to keep every team member informed and aligned.

- Construction Materials Management: Track inventory levels and manage materials procurement with ease, reducing waste and avoiding project delays.

- Construction Safety & Inspection Workflows: Implement customizable mobile forms for conducting safety inspections and managing compliance documentation effortlessly.

- Short-Term Scheduling: Visualize project tasks with detailed floor plans, linking each activity to specific locations for better planning accuracy.

- Construction Resource Management: Efficiently allocate personnel and equipment, maximizing productivity and reducing idle time.

StruxHub’s Product Offering:

- StruxHub Deliveries: Simplifies the coordination of incoming deliveries, ensuring materials and equipment are precisely timed to project needs.

- StruxHub Logistics: Offers intelligent site logistics planning, from crane scheduling to space allocation, for smoother operations.

- StruxHub Safety: Elevates on-site safety standards with easy-to-use tools for inspections, permits, and incident reporting.

- StruxHub Scheduling: Enhances project timelines with intuitive scheduling tools that ensure tasks are completed efficiently and on time.

With StruxHub, construction companies can look forward to a streamlined, more efficient project execution that delivers on time and within budget. Embrace the power of innovation and take your construction projects to the next level.

Don’t miss out on the opportunity to optimize your construction management processes with StruxHub. Sign up for a free demo today. Let’s build smarter, together.

FAQ’s

1. How is AI used in construction project management?

AI is transforming construction project management by optimizing scheduling, resource allocation, and decision-making processes. For instance, AI-powered software can analyze past project data to forecast project timelines, allowing managers to identify potential delays and make adjustments proactively. AI algorithms also analyze real-time data from active projects, enabling managers to allocate resources where they are most needed, improving overall efficiency and productivity.

In addition to scheduling, AI plays a significant role in predictive analytics. By analyzing vast datasets, AI can identify patterns that humans might miss, such as seasonal delays or resource bottlenecks. This helps construction managers anticipate issues and manage risks more effectively, reducing project costs and timelines.

AI also enhances communication across construction teams. Through automated notifications and centralized data sharing, AI ensures that all stakeholders are informed of project progress and any changes, reducing miscommunication and helping teams stay aligned on project goals.

2. What tasks can robotics perform on a construction site?

Robotics can handle a range of tasks on construction sites, from repetitive and physically demanding jobs to high-risk activities. For example, robots can assist with bricklaying, welding, and material handling, which are traditionally labor-intensive tasks. By automating these processes, robots help increase productivity and reduce the risk of workplace injuries.

Robots also play a critical role in tasks that are hazardous to humans. For instance, demolition robots can safely dismantle structures in environments where human workers would be at risk. Additionally, robotic arms can handle heavy lifting, reducing the need for manual labor and improving workplace safety.

Autonomous drones are another form of robotics commonly used on construction sites. Drones capture real-time data, allowing for accurate site mapping, progress tracking, and inspections. This eliminates the need for manual inspections in risky areas and improves project oversight by providing visual updates throughout the project lifecycle.

3. How do AI and robotics improve safety in construction?

AI and robotics enhance safety by monitoring job sites in real-time, predicting hazards, and automating dangerous tasks. For instance, AI-based safety systems analyze data from cameras and sensors to detect potential risks, such as workers entering restricted areas or failing to wear personal protective equipment (PPE). These systems immediately alert site supervisors, allowing them to take preventive action before accidents occur.

Robotics contribute to safety by performing high-risk tasks that would otherwise put human workers in harm’s way. Robots handle tasks such as heavy lifting, demolition, and working at extreme heights, which reduces the likelihood of injury. Additionally, robotic exoskeletons assist workers in physically demanding jobs, providing extra support that reduces strain and minimizes the risk of musculoskeletal injuries.

The use of predictive maintenance is another safety benefit of AI. By monitoring machinery and equipment health in real-time, AI systems can forecast when a machine is likely to fail and require repairs, reducing the risk of equipment malfunctions that could cause accidents on-site.

4. What are the cost benefits of using AI and robotics in construction?

The cost benefits of AI and robotics in construction are significant, mainly due to reduced labor costs, minimized waste, and increased efficiency. AI-powered scheduling and resource allocation tools help ensure that projects stay on track, preventing costly delays and minimizing the need for additional labor. This efficiency translates to lower labor costs and faster project completion times.

Robotics reduce material waste by performing tasks with precision. For example, automated machinery can cut materials to exact specifications, reducing excess and saving on material costs. In addition, predictive maintenance systems powered by AI help construction companies avoid costly equipment breakdowns by addressing maintenance needs before issues arise, reducing downtime and repair costs.

AI also enhances cost control by providing real-time insights into project expenses. By tracking spending against budget forecasts, construction managers can identify and address budget overruns before they escalate, leading to better financial outcomes and improved project profitability.