OFCI vs. CFCI: Which Procurement Method is Right for Your Project?

Table of Contents:

When planning a construction project, choosing the right procurement method can significantly impact cost, quality, and timeline. Two common approaches are Owner Furnished, Contractor Installed (OFCI) and Contractor Furnished, Contractor Installed (CFCI). Each method offers distinct advantages and challenges, and the decision often depends on the project’s complexity, budget, and the owner’s level of involvement.

This guide explores the key differences between OFCI and CFCI, their benefits, challenges, and how to decide which approach is best suited for your project.

What Is OFCI in Construction?

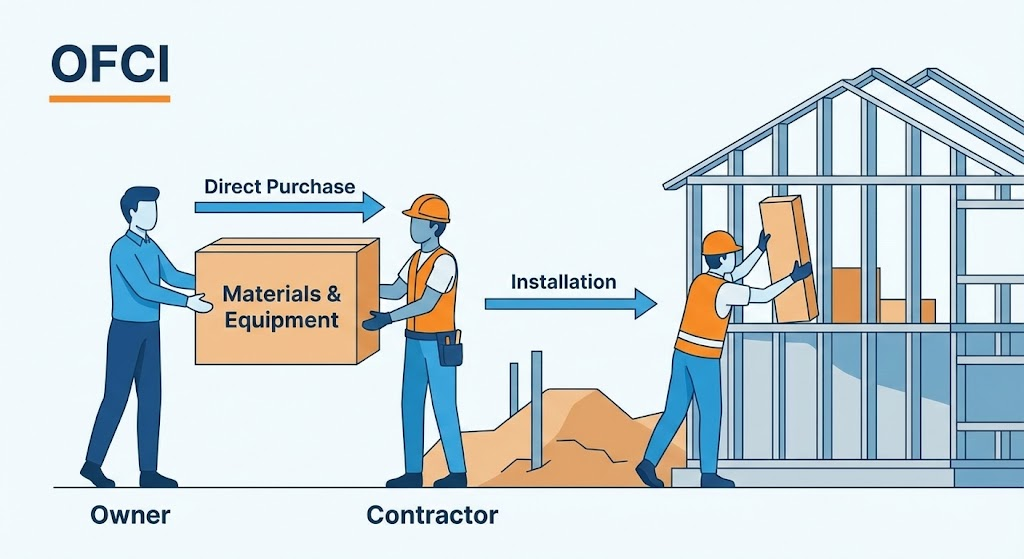

OFCI stands for Owner Furnished, Contractor Installed, a procurement method where the project owner purchases materials and equipment directly from vendors, while the contractor is responsible for installation. This approach is commonly used in projects requiring specialized items or where cost control and quality assurance are top priorities.

In OFCI, the owner negotiates directly with suppliers, eliminating contractor markups. This transparency not only reduces costs but also ensures that materials meet specific standards. However, OFCI demands more involvement from the owner, including managing logistics, coordinating delivery schedules, and addressing storage requirements.

Key Benefits

- Cost Savings: Eliminates contractor markups.

- Quality Assurance: Owners control the selection of materials and equipment.

- Customization: Tailored sourcing for specialized needs.

Best Practices

- Plan for Logistics: Ensure materials are delivered on time and stored properly.

- Communicate with Contractors: Keep contractors informed about specifications and schedules.

- Use Tracking Tools: Leverage project management platforms for seamless coordination.

What Is CFCI in Construction?

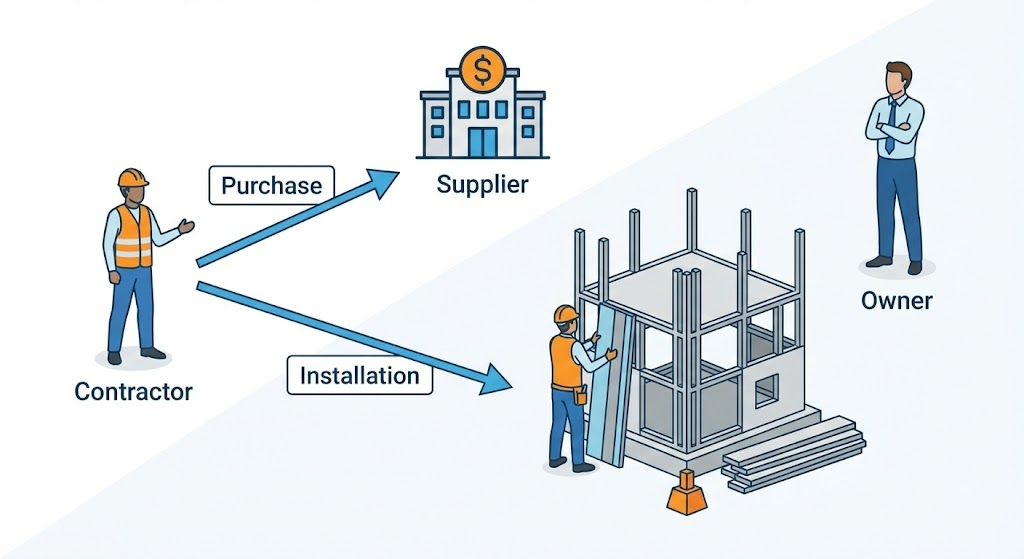

CFCI, or Contractor Furnished, Contractor Installed, is a more traditional procurement method where the contractor is responsible for both purchasing and installing materials. This approach simplifies the owner’s role and shifts much of the responsibility to the contractor.

Key Benefits

- Reduced Owner Involvement: The contractor handles procurement and logistics.

- Expert Sourcing: Contractors leverage their relationships with suppliers.

- Streamlined Workflow: Fewer coordination requirements between owners and contractors.

Best Practices

- Choose Reliable Contractors: Ensure contractors have a track record of effective procurement.

- Set Clear Expectations: Define quality standards and delivery timelines in the contract.

- Monitor Costs: Request transparency in pricing to avoid inflated costs.

How Do OFCI and CFCI Compare?

Understanding the differences between OFCI and CFCI is essential for choosing the right method for your project. While OFCI offers cost savings and control, it requires active owner involvement. CFCI, on the other hand, shifts responsibilities to the contractor but comes with higher costs and less transparency.

| Criteria | OFCI | CFCI |

| Cost | Lower (no contractor markups) | Higher (includes contractor markups) |

| Owner Involvement | High | Low |

| Control | Owners control material selection and quality | Contractors handle procurement decisions |

| Risk | Shared between owners and contractors | Primarily borne by the contractor |

When Should You Use OFCI?

OFCI (Owner Furnished, Contractor Installed) is a procurement strategy ideally suited for projects that require specialized equipment or materials, such as those in the healthcare, industrial, or tech sectors. These projects often involve unique or high-value components like MRI machines, industrial HVAC systems, or specialized lab equipment that owners need to source directly to meet specific standards or compliance requirements. OFCI allows owners to maintain direct oversight of these critical items, ensuring quality and compatibility with the overall project design.

Another scenario where OFCI is advantageous is when the owner has strong vendor relationships or the expertise to negotiate better pricing and terms. This approach not only eliminates contractor markups but also increases transparency in procurement, giving the owner greater control over budget allocation. Owners who prioritize sustainability or custom solutions may also favor OFCI, as it enables them to source materials that align with their project’s environmental or aesthetic goals.

However, OFCI requires owners to be actively involved in the procurement process. This includes managing vendor relationships, coordinating delivery schedules, and ensuring proper storage of materials until installation. It’s most effective for projects with well-defined timelines and minimal risk of delays, as late deliveries or miscommunication can lead to costly setbacks.

For successful implementation, owners must have the resources, expertise, and time to handle these responsibilities. If the owner lacks the capacity to manage procurement or the project involves tight deadlines with little room for error, alternative procurement methods might be more suitable. When used effectively, OFCI can provide significant cost savings, enhanced quality control, and the flexibility to customize materials and equipment for specialized needs.

When Should You Use CFCI?

CFCI (Contractor Furnished, Contractor Installed) is a preferred procurement strategy for projects where the owner wants to delegate procurement responsibilities entirely to the contractor. This approach is particularly beneficial for fast-track or high-volume projects, such as residential developments, office buildings, or large-scale commercial facilities, where standardized materials are required, and speed is a priority.

By allowing the contractor to handle both sourcing and installation, CFCI minimizes the owner’s workload and shifts the responsibility for procurement logistics, delivery coordination, and quality checks to the contractor. Contractors typically have established relationships with suppliers, enabling them to secure materials quickly and efficiently. Their expertise in managing procurement reduces the likelihood of delays caused by miscommunication or logistical challenges.

However, the trade-off for this convenience is higher costs. Contractors often include markups on materials to account for their procurement efforts, which can inflate the project budget. Additionally, the owner has limited visibility into material selection, which may result in lower-quality items or products that don’t fully align with the owner’s preferences. To mitigate this, owners should clearly define quality standards, delivery timelines, and acceptable suppliers in the contract.

CFCI is particularly useful for owners who lack procurement expertise or resources to manage the complexities of sourcing. It also works well when the contractor’s knowledge and relationships are crucial for acquiring specialized materials. While it may come at a higher cost, CFCI provides simplicity, convenience, and a streamlined process, making it a good fit for projects with tight schedules or limited owner involvement.

Unlock the Full Potential of Your Construction Projects with StruxHub

StruxHub enhances efficiency and coordination across all project phases, providing a single source of truth that eliminates silos and fosters collaboration. Real-time updates, financial management tools, and seamless commvunication features ensure that all team members and stakeholders are aligned and informed, reducing the risk of errors and delays. With comprehensive solutions for document management, risk mitigation, and quality control, StruxHub maintains project integrity and safety, while mobile access and integration capabilities further enhance project flexibility and efficiency.

StruxHub’s Key Features and Benefits:

- Advanced Delivery Management: Automate and optimize your delivery schedules, ensuring materials arrive just in time, every time.

- Site Communication: Utilize georeferenced maps and instant messaging to keep every team member informed and aligned.

- Construction Materials Management: Track inventory levels and manage materials procurement with ease, reducing waste and avoiding project delays.

- Construction Safety & Inspection Workflows: Implement customizable mobile forms for conducting safety inspections and managing compliance documentation effortlessly.

- Short-Term Scheduling: Visualize project tasks with detailed floor plans, linking each activity to specific locations for better planning accuracy.

- Construction Resource Management: Efficiently allocate personnel and equipment, maximizing productivity and reducing idle time.

StruxHub

Experience the power of StruxHub today and witness firsthand how it can revolutionize your construction operations.

StruxHub’s Product Offering:

- StruxHub Deliveries: Simplifies the coordination of incoming deliveries, ensuring materials and equipment are precisely timed to project needs.

- StruxHub Logistics: Offers intelligent site logistics planning, from crane scheduling to space allocation, for smoother operations.

- StruxHub Safety: Elevates on-site safety standards with easy-to-use tools for inspections, permits, and incident reporting.

- StruxHub Scheduling: Enhances project timelines with intuitive scheduling tools that ensure tasks are completed efficiently and on time.

With StruxHub, construction companies can look forward to a streamlined, more efficient project execution that delivers on time and within budget. Embrace the power of innovation and take your construction projects to the next level.

Don’t miss out on the opportunity to optimize your construction management processes with StruxHub. Sign up for a free demo today. Let’s build smarter, together.

Related Articles:

The Best Guide to OFCI in Construction: What Are Owner Furnished, Contractor Installed Projects?

45 Benefits and Tips of Construction Management Software for Superintendents

Best Guide to Construction Management Software

FAQs

1. What are the main differences between OFCI and CFCI?

The primary difference between OFCI (Owner Furnished, Contractor Installed) and CFCI (Contractor Furnished, Contractor Installed) lies in who handles the procurement of materials and equipment. In OFCI, the project owner takes on the responsibility of purchasing materials and equipment directly from suppliers. The contractor’s role is limited to installing these owner-provided items. Conversely, in CFCI, the contractor is responsible for both purchasing and installing materials, offering a more streamlined approach for the owner.

OFCI is often chosen for projects where the owner wants more control over material quality or pricing. By negotiating directly with suppliers, owners can ensure that materials meet specific standards while avoiding contractor markups. This transparency can lead to significant cost savings and better alignment with project goals. However, the owner assumes greater responsibility for coordinating procurement, managing delivery schedules, and addressing any issues with the materials.

CFCI shifts the burden of procurement to the contractor. This method is particularly beneficial for owners who lack the expertise or resources to manage procurement logistics. The contractor’s relationships with suppliers can streamline the purchasing process and ensure timely delivery. However, this convenience comes at a cost, as contractors typically include markups on materials and may have less incentive to prioritize cost savings for the owner.

While OFCI provides cost control and customization, it requires active involvement from the owner. On the other hand, CFCI offers convenience and reduced owner responsibilities but at a higher cost and with less visibility into procurement. Choosing between these methods depends on the owner’s priorities, budget, and capacity to manage procurement tasks. For complex projects requiring specialized materials, OFCI may be the better choice, whereas CFCI is ideal for simpler, fast-track projects.

2. Which method is more cost-effective: OFCI or CFCI?

When it comes to cost-effectiveness, OFCI generally has the upper hand, but it depends on the project’s specific requirements and the owner’s ability to manage procurement effectively. In OFCI, the owner negotiates directly with vendors, eliminating contractor markups that are typically included in CFCI. This direct approach not only reduces costs but also provides transparency in pricing, allowing the owner to align procurement with the project’s budget.

For example, if an owner procures high-value HVAC systems through OFCI, they may save a substantial amount compared to having the contractor handle the purchase. Contractors often include a percentage-based markup on materials to cover their procurement efforts, which can inflate costs. Additionally, in OFCI, owners can source materials from their preferred vendors, potentially negotiating bulk discounts or taking advantage of long-term supplier relationships.

However, OFCI’s cost-effectiveness relies on the owner’s ability to manage procurement efficiently. Poorly coordinated deliveries or delays in vendor negotiations can lead to increased storage costs or idle labor, offsetting the initial savings. Owners must also invest time and resources in managing vendor relationships, tracking orders, and ensuring that materials meet quality standards.

In contrast, CFCI may appear more expensive due to contractor markups, but it offers convenience and efficiency. Contractors, with their established supplier networks, can often secure materials more quickly and with less hassle. For owners who lack the resources or expertise to manage procurement, the additional cost of CFCI can be justified as it reduces their workload and shifts the risk of procurement to the contractor.

Ultimately, OFCI is more cost-effective for owners who are willing and able to handle procurement responsibilities. For projects where convenience and efficiency outweigh cost savings, CFCI may be the better option. Evaluating the project’s complexity, budget, and timeline will help determine which method delivers the best value.

3. How do I decide between OFCI and CFCI for my project?

Choosing between OFCI and CFCI depends on several factors, including the project’s complexity, budget, and the level of involvement the owner is willing to take on. Understanding the strengths and limitations of each method can help you make an informed decision that aligns with your project goals.

OFCI is an excellent choice for projects that require specialized materials or equipment. For instance, in healthcare construction, owners often opt for OFCI to procure medical equipment that meets specific compliance standards. This approach allows owners to negotiate directly with vendors, ensuring cost savings and quality control. However, OFCI requires the owner to manage procurement logistics, including delivery schedules, storage, and inspections. If the owner has the expertise and resources to handle these responsibilities, OFCI can be a highly cost-effective and efficient method.

On the other hand, CFCI is ideal for projects where the owner prefers to delegate procurement responsibilities. This approach is particularly beneficial for fast-track projects or when the contractor’s expertise is needed to source complex materials. In CFCI, the contractor handles procurement and installation, reducing the owner’s workload. However, this convenience often comes at a higher cost due to contractor markups, and the owner has less control over material selection.

To decide between the two, consider the following:

- Budget Constraints: OFCI may save costs but requires investment in procurement management.

- Project Complexity: OFCI is better for specialized materials, while CFCI suits standard construction projects.

- Owner Expertise: If the owner lacks procurement experience, CFCI may be the safer option.

Discussing these factors with your project team, including contractors and consultants, can provide valuable insights into which method best meets your needs.

4. What are the risks of using OFCI?

While OFCI (Owner Furnished, Contractor Installed) offers several benefits, such as cost savings, greater control over materials, and quality assurance, it also comes with specific risks that owners must carefully manage to ensure project success. These risks often stem from the split responsibilities between procurement (handled by the owner) and installation (handled by the contractor), which can lead to coordination challenges and disputes.

Coordination Challenges:

One of the most common risks in OFCI is the misalignment between material delivery schedules and contractor timelines. If materials arrive too late, contractors may face delays, which can disrupt the entire project. Conversely, early deliveries can lead to storage issues, additional costs, or material damage. Effective planning and the use of tools like project management software are crucial to minimizing this risk.

Material Quality Issues:

Since the contractor does not procure the materials, they may have limited ability to address issues related to quality, specifications, or compatibility. If the delivered items fail to meet project requirements, it can result in delays, rework, or disputes over who is responsible for replacements.

Liability Concerns:

Determining responsibility for damaged, defective, or missing materials can be challenging in OFCI arrangements. Contracts must clearly define whether the owner, vendor, or contractor is liable for issues that arise during procurement or delivery. Without these clauses, disputes can stall progress and increase costs.

Increased Owner Responsibility:

OFCI places a significant burden on the owner to manage procurement logistics, vendor relationships, and quality control. Owners who lack expertise or resources may struggle to meet these demands, leading to project inefficiencies.

Vendor Risks:

Reliance on third-party vendors introduces additional risks, such as supply chain disruptions or delivery delays. Vetting vendors and establishing clear agreements are essential steps to mitigate these risks.

5. Can OFCI and CFCI be combined in a single project?

Yes, a hybrid approach combining OFCI and CFCI can be an effective solution for many construction projects. This strategy allows owners to balance cost savings and convenience by leveraging the strengths of both procurement methods.

For example, an owner might use OFCI for high-value or specialized equipment, such as HVAC systems or medical devices, where cost control and quality assurance are priorities. At the same time, they could delegate the procurement of standard materials like drywall or concrete to the contractor under CFCI. This division of responsibilities ensures that the owner maintains oversight of critical components while reducing their involvement in routine purchases.

Combining OFCI and CFCI requires careful planning and coordination. It’s essential to establish clear contracts that outline which materials fall under each procurement method. For instance, the contract should specify delivery schedules, quality standards, and liability for damaged or delayed items. Without clear guidelines, the hybrid approach can lead to miscommunication or disputes.

One of the key benefits of this approach is flexibility. It allows owners to focus their efforts on areas where their involvement adds the most value, while contractors handle less critical tasks. Additionally, it provides opportunities for cost savings on specialized items without overburdening the owner with logistical responsibilities.

To implement this hybrid model successfully, use project management tools to track procurement activities and maintain open communication with all stakeholders. Regular updates and alignment meetings ensure that both parties understand their roles and responsibilities, preventing delays and ensuring project continuity.

By combining OFCI and CFCI strategically, owners can optimize both cost and efficiency, creating a tailored procurement strategy that meets the unique demands of their project.