What is OFCI in Construction? A Guide to Owner Furnished, Contractor Installed Projects

Table of Contents:

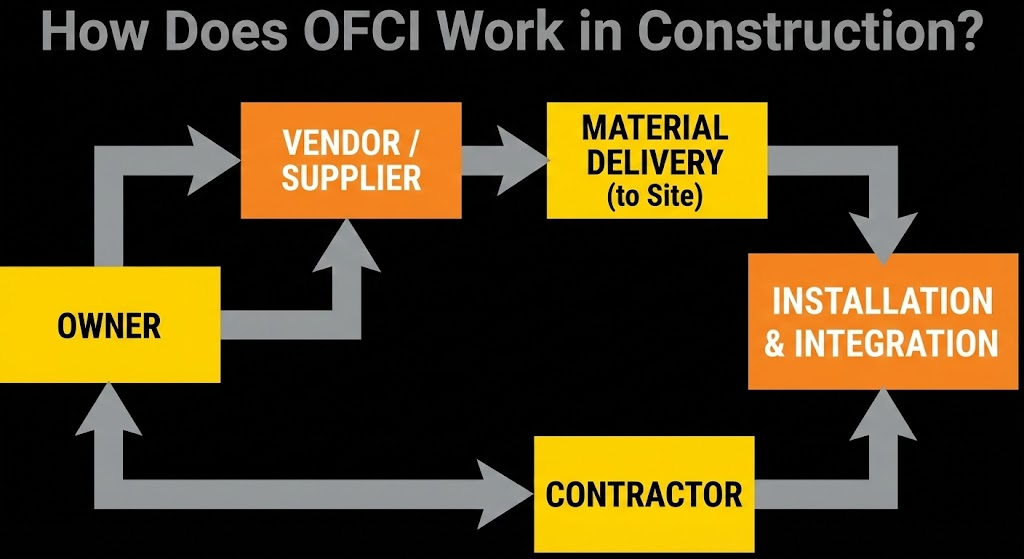

In construction, efficient procurement strategies significantly influence project outcomes. Owner Furnished, Contractor Installed (OFCI) is a specialized approach where the project owner takes charge of sourcing materials and equipment while the contractor handles installation. This division of responsibilities empowers owners to control costs, ensure quality, and source custom solutions tailored to project requirements.

This guide dives deep into OFCI, exploring how it works, its benefits, challenges, best practices, and how it compares to other procurement methods. By understanding the intricacies of OFCI, you can determine if it’s the right choice for your next construction project.

How Does OFCI Work in Construction?

OFCI (Owner Furnished, Contractor Installed) splits procurement and installation responsibilities. The project owner procures materials directly from vendors, leveraging control over cost and quality, while the contractor focuses solely on installation. This setup is commonly used in specialized projects, such as hospitals or industrial facilities, where the owner’s input is critical.

For example, in a commercial office project, the owner might purchase custom lighting fixtures directly from a preferred supplier. The contractor’s role is to install these fixtures as per the project specifications. While this method provides transparency and customization, it demands careful planning and communication.

Key Benefits

- Cost Efficiency: Owners eliminate contractor markups by directly negotiating with suppliers.

- Quality Control: Owners ensure materials meet specific standards.

- Customization: Perfect for sourcing specialized or unique materials.

Best Practices

- Set Clear Expectations: Define roles, responsibilities, and timelines in contracts.

- Coordinate Deliveries: Align material delivery schedules with contractor needs.

- Use Technology: Tools like StruxHub enhance procurement tracking and communication.

Conclusion

OFCI empowers owners to take charge of procurement, ensuring that critical project elements align with their vision. However, its success depends on precise coordination and the ability to manage procurement logistics effectively.

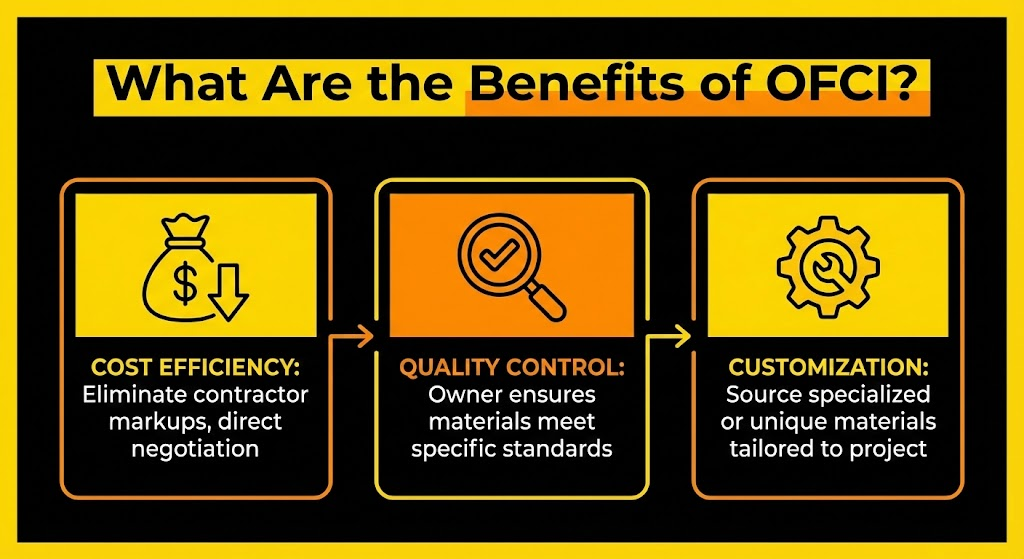

What Are the Benefits of OFCI?

The advantages of OFCI lie in its transparency and flexibility. By taking control of procurement, owners can avoid contractor markups, gain insight into material costs, and ensure that everything meets the required standards.

This method is especially beneficial for projects requiring specialized materials. Owners can negotiate terms directly with vendors, ensuring they receive the best pricing and quality. Furthermore, OFCI allows for greater adaptability in responding to changing project needs, as owners can adjust procurement strategies as necessary.

However, the benefits of OFCI are only realized if owners have the resources and expertise to manage procurement logistics. Proper planning and coordination are vital to avoid disruptions.

Key Benefits

- Cost Savings: Negotiate better prices by bypassing contractor markups.

- Transparency: Full visibility into procurement processes.

- Customization: Tailored solutions for unique project requirements.

Best Practices

- Build Strong Vendor Relationships: Collaborate with trusted suppliers for long-term success.

- Align Procurement and Installation: Use tools to synchronize deliveries with project timelines.

- Document Processes: Keep detailed records of procurement activities for accountability.

OFCI provides owners with unparalleled control over materials and costs. With the right planning and coordination, it ensures project efficiency and quality.

Related Articles:

OFCI vs. CFCI: Which Procurement Method is Right for Your Project?

The Best Guide to OFCI in Construction: What Are Owner Furnished, Contractor Installed Projects?

The Best Guide to Delivery Management Systems (DMS) for Commercial Construction

Best Guide to Construction Management Software

What Are the Challenges of OFCI?

While OFCI offers numerous advantages, it comes with challenges. Miscommunication, logistical delays, and liability disputes are common issues that can derail projects. For example, if materials arrive late, contractors may face downtime, resulting in additional costs. Alternatively, early deliveries may lead to storage issues or material damage.

Liability disputes also arise in OFCI arrangements, especially if materials are damaged in transit or don’t meet specifications. Establishing clear contracts that define roles and responsibilities is essential to avoid such conflicts.

OFCI also demands a high level of involvement from the owner, requiring resources and expertise to manage procurement effectively. Without careful planning, the risks can outweigh the benefits.

Key Benefits

- Risk Management: Contracts help clarify responsibilities and minimize disputes.

- Streamlined Operations: Clear planning reduces delays.

- Enhanced Accountability: Transparency ensures all parties meet their obligations.

Best Practices

- Create Contingency Plans: Account for potential delays or disruptions.

- Use Reliable Vendors: Partner with suppliers known for their consistency and quality.

- Implement Advanced Tools: Platforms like StruxHub streamline procurement management.

OFCI’s challenges require proactive management. With proper contracts, vendor selection, and advanced planning, owners can mitigate risks and achieve success.

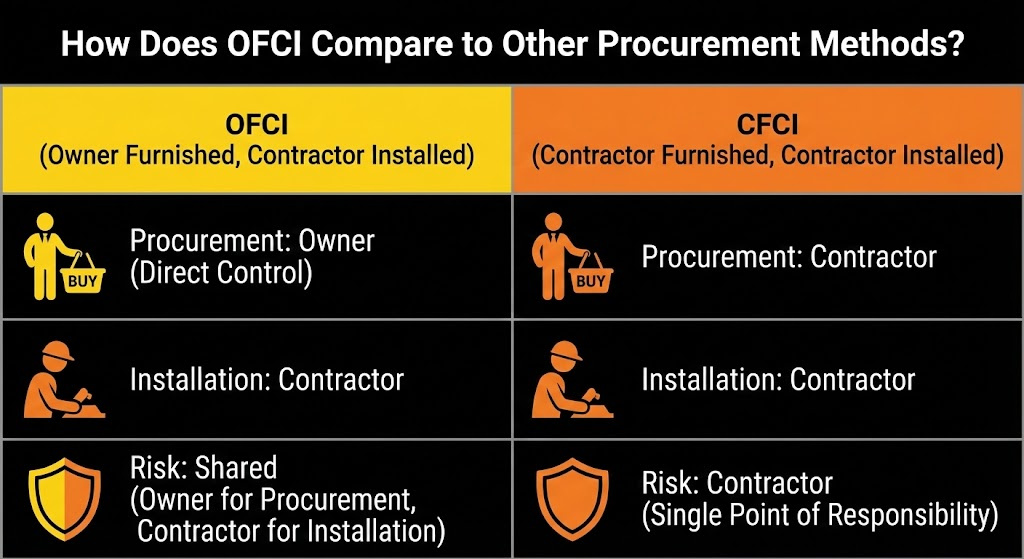

How Does OFCI Compare to Other Procurement Methods?

OFCI stands apart from methods like Contractor Furnished, Contractor Installed (CFCI) due to its focus on owner control. While CFCI simplifies the process by shifting procurement responsibilities to the contractor, it comes with higher costs and less visibility into material selection.

In contrast, OFCI allows owners to maintain oversight of critical project components, ensuring cost transparency and quality assurance. This makes OFCI ideal for projects requiring specialized materials or tight budget control. However, it demands more involvement from the owner compared to CFCI.

Key Benefits

- Transparency: OFCI provides a clear view of procurement costs and processes.

- Flexibility: Owners can adjust procurement to meet changing project needs.

- Efficiency: Allows contractors to focus on installation expertise.

Best Practices

- Evaluate Project Needs: Assess whether the owner’s involvement aligns with project goals.

- Establish Clear Contracts: Define roles and responsibilities to avoid conflicts.

- Monitor Costs: Use tools like StruxHub to track expenses.

OFCI offers unmatched control for owners seeking cost transparency and quality assurance. However, it’s essential to weigh its demands against the simplicity of CFCI.

Related Articles:

Indiana’s Mega Construction Project: Meta’s $800M Data Center

How Does OFCI Impact Project Timelines?

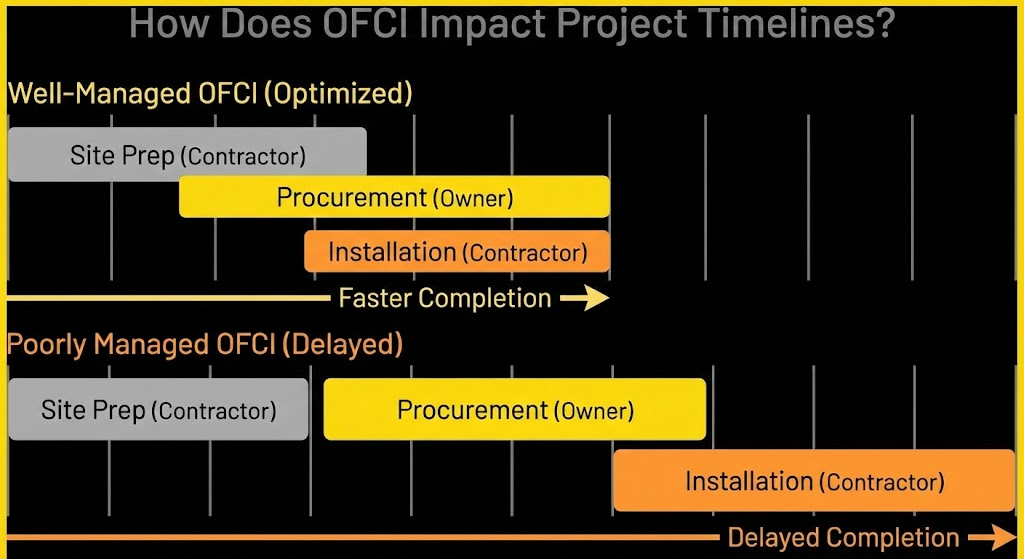

OFCI (Owner Furnished, Contractor Installed) can have both positive and negative effects on project timelines, depending on how well it is managed. On the positive side, OFCI allows owners to procure materials while contractors focus on installation, creating an overlap that can streamline schedules. For instance, while the contractor is preparing the site, the owner can arrange for critical materials to arrive just in time for installation.

However, poor coordination can lead to delays. If materials are delivered late or incomplete, contractors may face downtime, delaying subsequent tasks. Early deliveries can also create bottlenecks if storage is insufficient or the materials obstruct site operations.

Key factors that influence OFCI’s impact on timelines include vendor reliability, delivery coordination, and contractor flexibility. Owners who fail to establish clear timelines or vet their suppliers risk misalignments that can derail progress.

Key Benefits

- Optimized Workflow: Allows simultaneous procurement and construction activities.

- Controlled Scheduling: Owners set delivery timelines that align with project milestones.

- Mitigated Risks: Advanced planning reduces the likelihood of timeline disruptions.

Best Practices

- Coordinate Early: Develop a detailed schedule that integrates procurement and construction activities.

- Use Just-in-Time Delivery: Minimize storage issues and optimize site efficiency.

- Monitor Progress: Use tools like StruxHub for real-time updates on procurement and scheduling.

OFCI can streamline timelines when properly managed, but it requires meticulous planning and coordination to avoid disruptions. With the right approach, it becomes a powerful tool for efficient project execution.

What Are the Liability Concerns in OFCI Projects?

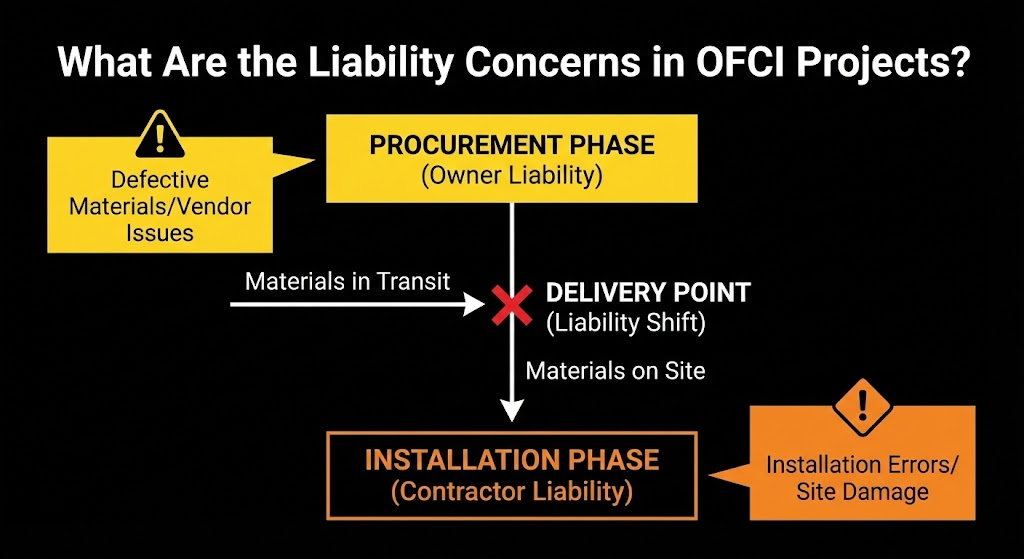

Liability is a critical concern in OFCI projects, as the division of responsibilities between owners and contractors creates potential gray areas. For example, who is responsible if a material is damaged during delivery or if it doesn’t meet the specified standards? Without clear agreements, disputes over such issues can lead to delays and additional costs.

Owners typically bear the risk during procurement, including vendor selection and transportation. Once the materials are delivered to the site, liability often shifts to the contractor. However, this transition must be clearly defined in the contract to prevent misunderstandings.

Liability issues can also arise during installation if materials are defective or incompatible with the project’s design. In these cases, it’s essential to determine whether the fault lies with the owner’s procurement process or the contractor’s installation methods.

Key Benefits

- Defined Accountability: Contracts clarify roles and responsibilities, reducing disputes.

- Risk Mitigation: Proper planning minimizes liability issues.

- Improved Collaboration: Transparent processes foster trust between owners and contractors.

Best Practices

- Draft Clear Contracts: Specify liability for procurement, delivery, and installation.

- Inspect Deliveries: Conduct thorough inspections upon material arrival.

- Establish Communication Protocols: Ensure quick resolution of disputes to avoid delays.

Managing liability in OFCI projects requires clear contracts, diligent inspections, and open communication. These steps ensure accountability and minimize risks, keeping the project on track.

Can OFCI Be Used in Combination with Other Procurement Methods?

StruxHub

Experience the power of StruxHub today and witness firsthand how it can revolutionize your construction operations.

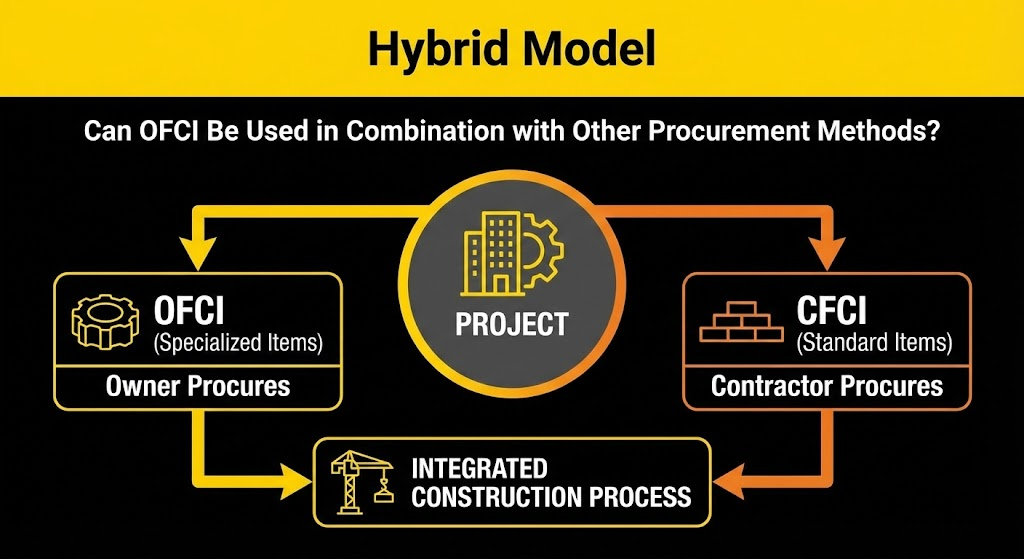

Yes, OFCI can be integrated with other procurement methods, such as Contractor Furnished, Contractor Installed (CFCI), to create a hybrid approach that balances cost control and convenience. For example, an owner might use OFCI for high-value or specialized equipment while allowing the contractor to procure and install standard materials through CFCI.

This hybrid strategy provides flexibility, enabling owners to focus on critical components while delegating routine tasks to the contractor. It is particularly beneficial for large or complex projects where certain elements require direct owner oversight, but others can be managed more efficiently by the contractor.

However, combining procurement methods requires clear contracts to avoid confusion. For instance, the contract should specify which items fall under OFCI and which are covered by CFCI. Additionally, regular communication is essential to ensure both parties understand their responsibilities.

Key Benefits

- Balanced Workload: Owners focus on critical items, while contractors handle routine materials.

- Cost Savings: OFCI reduces costs for specialized items, while CFCI simplifies standard procurement.

- Flexibility: Adaptable to the specific needs of the project.

Best Practices

- Define Procurement Scope: Clearly outline which materials are owner-furnished and which are contractor-furnished.

- Coordinate Schedules: Align delivery and installation timelines across both methods.

- Leverage Technology: Use tools like StruxHub to track procurement progress and integration.

Using OFCI in combination with other procurement methods allows for a tailored approach that optimizes cost, quality, and efficiency. Clear communication and contracts are essential for success.

Unlock the Full Potential of Your Construction Projects with StruxHub

StruxHub enhances efficiency and coordination across all project phases, providing a single source of truth that eliminates silos and fosters collaboration. Real-time updates, financial management tools, and seamless commvunication features ensure that all team members and stakeholders are aligned and informed, reducing the risk of errors and delays. With comprehensive solutions for document management, risk mitigation, and quality control, StruxHub maintains project integrity and safety, while mobile access and integration capabilities further enhance project flexibility and efficiency.

StruxHub’s Key Features and Benefits:

- Advanced Delivery Management: Automate and optimize your delivery schedules, ensuring materials arrive just in time, every time.

- Site Communication: Utilize georeferenced maps and instant messaging to keep every team member informed and aligned.

- Construction Materials Management: Track inventory levels and manage materials procurement with ease, reducing waste and avoiding project delays.

- Construction Safety & Inspection Workflows: Implement customizable mobile forms for conducting safety inspections and managing compliance documentation effortlessly.

- Short-Term Scheduling: Visualize project tasks with detailed floor plans, linking each activity to specific locations for better planning accuracy.

- Construction Resource Management: Efficiently allocate personnel and equipment, maximizing productivity and reducing idle time.

StruxHub’s Product Offering:

- StruxHub Deliveries: Simplifies the coordination of incoming deliveries, ensuring materials and equipment are precisely timed to project needs.

- StruxHub Logistics: Offers intelligent site logistics planning, from crane scheduling to space allocation, for smoother operations.

- StruxHub Safety: Elevates on-site safety standards with easy-to-use tools for inspections, permits, and incident reporting.

- StruxHub Scheduling: Enhances project timelines with intuitive scheduling tools that ensure tasks are completed efficiently and on time.

With StruxHub, construction companies can look forward to a streamlined, more efficient project execution that delivers on time and within budget. Embrace the power of innovation and take your construction projects to the next level.

Don’t miss out on the opportunity to optimize your construction management processes with StruxHub. Sign up for a free demo today. Let’s build smarter, together.

FAQ

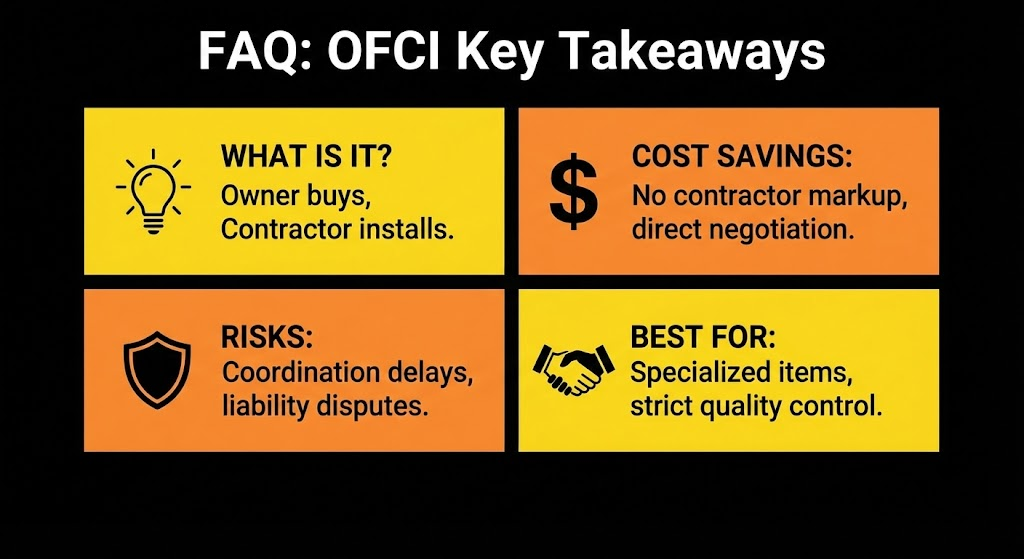

1. What is OFCI in construction?

OFCI, or Owner Furnished, Contractor Installed, is a procurement method where the owner of a project is responsible for purchasing materials and equipment, while the contractor installs them as part of the construction process. This approach allows owners to retain direct control over the procurement of critical or specialized materials, ensuring they meet quality standards, are acquired at a favorable cost, and align with the overall project requirements.

OFCI is commonly used in projects requiring high-value or industry-specific items, such as medical equipment in hospitals, advanced HVAC systems in commercial spaces, or specialized machinery in industrial facilities. Owners often choose OFCI when they have established relationships with trusted vendors or when the project requires materials that meet precise specifications.

One of the key advantages of OFCI is cost savings. By eliminating contractor markups, owners can negotiate directly with suppliers to secure better pricing and terms. However, this approach also places significant responsibility on the owner to manage procurement logistics, including delivery schedules, inspections, and storage. Missteps in these areas can lead to delays, disputes, or increased costs.

Contractual agreements are crucial for the success of OFCI projects. Clear contracts should outline the responsibilities of both parties, including who is liable for damaged or delayed materials. The use of project management tools like StruxHub can help owners streamline procurement, track deliveries, and ensure alignment with construction timelines.

OFCI is an excellent choice for owners who prioritize cost transparency and quality control but requires meticulous planning and strong coordination with contractors and vendors to execute successfully.

2. How does OFCI reduce project costs?

OFCI reduces project costs primarily by eliminating contractor markups on materials and equipment. In traditional procurement methods, contractors purchase materials on behalf of the owner and often include a markup as compensation for their efforts. This markup can significantly increase project costs, especially in large-scale or high-budget projects. By opting for OFCI, owners bypass this markup, negotiating directly with vendors to achieve better pricing.

For example, in a commercial office project, an owner may choose to procure custom-designed lighting fixtures directly from a manufacturer. By cutting out the contractor’s markup, the owner ensures they pay only the actual cost of the fixtures and can often negotiate bulk discounts or more favorable payment terms.

Additionally, OFCI offers transparency in pricing. Owners have complete visibility into the procurement process, allowing them to allocate budgets more effectively and avoid hidden costs. This transparency is particularly beneficial in projects with strict budget constraints, as it enables owners to prioritize spending on high-value or specialized items.

Another cost-saving aspect of OFCI is the potential for better vendor relationships. Owners who directly manage procurement can establish long-term partnerships with reliable suppliers, leading to discounted rates or preferential treatment in future projects.

However, while OFCI can reduce costs, it requires careful management to prevent unforeseen expenses. Poorly coordinated deliveries, inadequate storage solutions, or defective materials can offset initial savings. Owners must invest time and resources into managing procurement logistics and use advanced tools, such as StruxHub, to monitor and streamline the process.

In summary, OFCI significantly reduces costs by removing contractor markups and providing full control over procurement. To maximize these savings, owners must plan meticulously, vet vendors carefully, and coordinate schedules effectively.

3. What are the risks of OFCI?

While OFCI offers significant benefits, it also comes with inherent risks that can impact the success of a project if not carefully managed. One of the most notable risks is delivery misalignment, where materials or equipment arrive too early or too late. Early deliveries can result in storage issues, increased costs, or potential damage to materials, while late deliveries can disrupt the contractor’s schedule, causing delays and additional labor expenses.

Another major risk in OFCI is liability disputes. Since the owner is responsible for procuring materials, any issues related to quality, damage during transport, or compatibility often fall on their shoulders. If materials do not meet the required standards or arrive damaged, contractors may refuse to install them, leading to delays and potentially costly replacements.

Coordination challenges are also prevalent in OFCI projects. Managing multiple vendors, aligning procurement with the contractor’s schedule, and ensuring materials meet specifications require significant effort and expertise. Miscommunication between owners, contractors, and suppliers can lead to misunderstandings, disputes, and inefficiencies.

Vendor reliability is another concern. Choosing an untrustworthy supplier increases the risk of receiving subpar materials, late deliveries, or no deliveries at all. Owners must carefully vet vendors and establish clear agreements to minimize this risk.

To mitigate these risks, owners should adopt several best practices:

- Draft Clear Contracts: Specify roles, responsibilities, and liability for each party.

- Conduct Inspections: Ensure materials meet quality standards upon delivery.

- Use Technology: Tools like StruxHub provide real-time tracking and streamline procurement logistics.

While the risks of OFCI can be significant, they are manageable with proper planning, open communication, and the use of advanced tools to coordinate procurement activities effectively.

4. When should you choose OFCI over other methods?

Choosing OFCI over other procurement methods depends on several factors, including the project’s complexity, budget, and the owner’s level of expertise in managing procurement. OFCI is ideal for projects where the owner seeks greater control over materials and equipment, such as those requiring specialized or high-value items.

For example, in healthcare construction, where compliance with strict standards is essential, OFCI allows owners to source medical equipment directly from trusted vendors. This ensures the equipment meets industry regulations and aligns with the project’s specific needs. Similarly, industrial projects often use OFCI for procuring custom machinery or systems that contractors may not have the expertise to source effectively.

Budget constraints also make OFCI an attractive option. By eliminating contractor markups, owners gain transparency in material costs, allowing them to allocate funds more efficiently. This method is particularly beneficial for large-scale projects, where even small percentage savings can result in significant cost reductions.

However, OFCI requires a high degree of owner involvement. Projects with tight timelines or owners lacking procurement expertise may be better suited for methods like Contractor Furnished, Contractor Installed (CFCI). In such cases, contractors take full responsibility for sourcing and installation, simplifying the owner’s role.

OFCI is most effective in well-planned projects with clear timelines and reliable suppliers. By combining owner control with contractor expertise, it ensures a balance between quality, cost savings, and project efficiency.