What’s the Difference Between Geographic Information Systems (GIS), BIM, and CAD in Construction Projects?

Table of Contents:

Why Is It Important to Understand GIS, BIM, and CAD in Construction?

Construction projects today are more technology-driven than ever. Tools like Geographic Information Systems (GIS), Building Information Modeling (BIM), and Computer-Aided Design (CAD) each play important roles in planning, design, and execution. While they often overlap in function, they are not interchangeable. Understanding the differences between them is critical for superintendents, project managers, and contractors who want to select the right tool for the right task.

GIS is all about location and context. It allows teams to analyze geographic data, such as terrain, soil types, utility lines, and environmental constraints. BIM focuses on the building itself, creating a 3D digital representation of structures that includes geometry, materials, and lifecycle data. CAD, on the other hand, is a design tool primarily used for drafting detailed 2D or 3D drawings of components and structures.

For large, complex projects like data centers, highways, or hospitals, these technologies often work together. GIS ensures the site is viable and integrates with surrounding infrastructure. BIM manages the design, construction, and eventual operations of the facility. CAD delivers the precision drawings needed to manufacture and install specific components.

Top Benefits

- Clarifies the role of each tool in the construction lifecycle.

- Helps teams avoid confusion and inefficiency.

- Enables better decision-making by selecting the right platform.

Best Practices for Understanding the Differences

- Map GIS, BIM, and CAD workflows to specific project phases.

- Train crews on when and how to use each system.

- Integrate the tools for maximum synergy on complex projects.

Recognizing how GIS, BIM, and CAD differ—and complement each other—can save time, money, and mistakes during construction.

What Is GIS and How Is It Applied in Construction Projects?

Geographic Information Systems (GIS) are powerful platforms designed to capture, analyze, and visualize spatial data. In construction, GIS helps teams understand the broader environmental and geographic context of a project site. Before breaking ground, contractors can use GIS to map soil stability, flood zones, transportation access, and proximity to utilities. This information is vital for reducing risks and ensuring compliance with environmental regulations.

GIS also plays a role throughout the construction lifecycle. During planning, it identifies optimal routes for material deliveries and equipment staging. During construction, it can track progress across large sites, integrating drone imagery, GPS-enabled equipment, and real-time data from the field. For infrastructure projects such as highways or pipelines, GIS ensures alignment with surrounding geography while highlighting conflicts with existing utilities or land features.

In the age of smart construction, GIS integrates with sensors and IoT devices to monitor environmental conditions like water flow or air quality. It is increasingly becoming a decision-making tool for both contractors and public agencies, offering visibility into how construction impacts entire regions rather than just a single site.

Top Benefits

- Improves site selection and risk management.

- Enables real-time monitoring of environmental conditions.

- Supports logistics planning for large or multi-site projects.

Best Practices for Using GIS in Construction

- Incorporate GIS early in the site planning phase.

- Combine GIS with drone and IoT data for real-time insights.

- Use GIS to coordinate with municipalities and utility providers.

GIS ensures construction projects are not just designed to fit a site, but harmonized with the surrounding environment and infrastructure.

What Is BIM and How Does It Differ from GIS?

Building Information Modeling (BIM) is a digital representation of a structure that goes far beyond traditional blueprints. Unlike GIS, which focuses on geographic context, BIM zeroes in on the building itself, capturing every detail in a 3D model that can be shared across project stakeholders.

BIM provides a holistic view of design and construction. It includes geometry, material properties, cost estimates, and even maintenance schedules. Contractors and superintendents use BIM to coordinate trades, reduce clashes between systems, and visualize how different components fit together before construction begins. For example, BIM can show whether HVAC ducts will conflict with electrical conduits in a ceiling space—issues that would be costly to fix onsite.

The key difference between BIM and GIS lies in scope. GIS answers questions like, “Where should this facility be built?” while BIM addresses, “How will this facility be built and operated?” The two are increasingly integrated, with GIS providing environmental and site data that informs the BIM model. Together, they create a powerful ecosystem of design and planning intelligence.

Top Benefits

- Improves collaboration across architects, engineers, and contractors.

- Reduces design errors and costly field rework.

- Supports lifecycle management beyond construction.

Best Practices for Using BIM in Construction

- Use BIM models for clash detection and trade coordination.

- Integrate BIM with GIS for full project context.

- Leverage BIM for both construction and facility management phases.

BIM is the go-to tool for bringing a construction project to life digitally, enabling teams to build smarter, faster, and with fewer surprises.

What Is CAD and How Does It Fit Into Construction Workflows?

Computer-Aided Design (CAD) is one of the oldest and most widely used digital tools in construction. Unlike GIS and BIM, CAD is not about holistic systems or geographic analysis—it is primarily a drafting and design tool. CAD software allows architects and engineers to create highly precise 2D drawings or 3D models of components, assemblies, and structures.

In construction workflows, CAD typically appears in the early design and detailing phases. Structural engineers use it to draft steel connections, architects rely on it for detailed floor plans, and MEP (mechanical, electrical, and plumbing) engineers design system layouts with it. These detailed drawings often form the foundation for BIM models and can be integrated into broader project documentation.

The main strength of CAD is accuracy. It provides exact dimensions and specifications that guide fabrication and installation. However, CAD lacks the data-rich context of BIM or the spatial awareness of GIS. On its own, CAD doesn’t track costs, schedules, or environmental factors—it simply ensures designs are drafted with precision.

Top Benefits

- Provides exact measurements and detailed drawings.

- Widely understood and adopted across engineering disciplines.

- Serves as the foundation for more advanced systems like BIM.

Best Practices for CAD in Construction

- Use CAD for precision detailing of components and assemblies.

- Integrate CAD drawings into BIM models for greater context.

- Maintain version control to avoid errors from outdated files.

CAD continues to be essential because precision remains at the core of construction—even as projects adopt more advanced digital platforms.

How Do GIS, BIM, and CAD Work Together on Construction Projects?

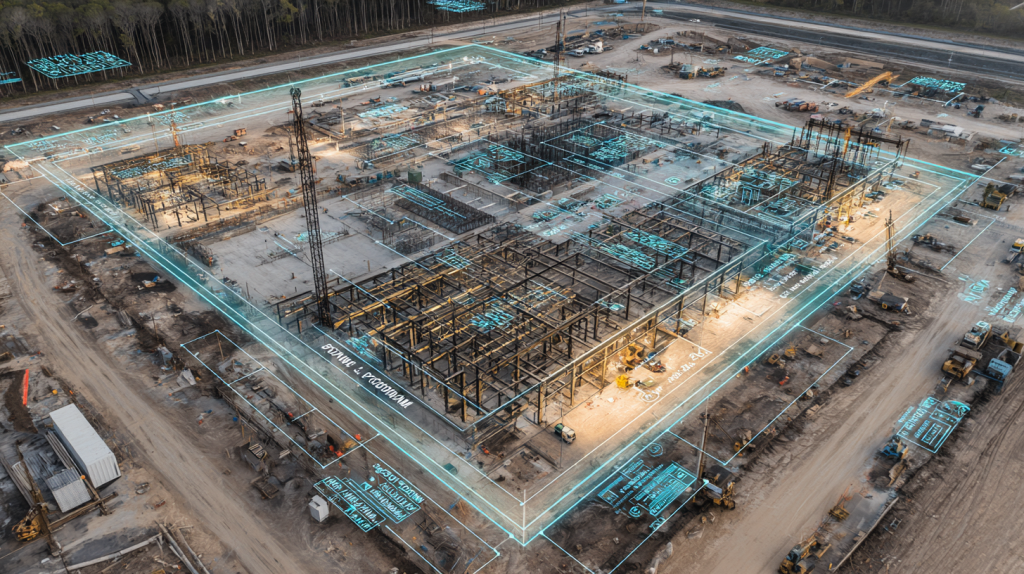

While GIS, BIM, and CAD each serve different purposes, their true power comes from integration. For large projects like highways, airports, or hyperscale data centers, these tools complement each other to create a seamless workflow from site selection to facility management.

GIS informs the project with environmental and geographic data. It identifies flood zones, soil conditions, and existing infrastructure, ensuring the site is viable. BIM then takes over, modeling the design of the building in detail, coordinating trades, and managing costs and schedules. CAD supports both by providing the precision drawings required to fabricate and install components accurately.

An example of integration might be a data center project. GIS ensures the land is suitable and identifies nearby utility lines. BIM creates a detailed digital model of the building, showing exactly how mechanical and electrical systems will fit together. CAD provides the shop drawings for steel fabrication and electrical panels. Together, they create an end-to-end digital ecosystem that reduces risk, saves time, and improves quality.

Top Benefits

- Creates continuity across planning, design, and construction phases.

- Reduces errors by integrating geographic, building, and design data.

- Improves collaboration between diverse project teams.

Best Practices for Integrating GIS, BIM, and CAD

- Establish data exchange standards early in the project.

- Use software platforms that support interoperability.

- Train teams on how to transition between tools smoothly.

Integration ensures these tools are not siloed but instead contribute to a unified workflow that enhances project outcomes.

What Challenges Do Contractors Face When Using GIS, BIM, and CAD Together?

While integration offers huge benefits, it also introduces challenges. Contractors often face issues with software interoperability—one platform may not communicate seamlessly with another, requiring data conversions that can lead to errors or lost detail. For example, transferring CAD files into BIM models can cause misalignments if standards are not carefully maintained.

Training is another hurdle. While most engineers are comfortable with CAD, fewer have expertise in BIM or GIS. Contractors must invest in training and upskilling crews to ensure teams use the tools effectively. Without this, the potential benefits of integration may be lost.

Cost is also a factor. Licensing multiple platforms, maintaining hardware capable of handling large models, and hiring specialists can be expensive. For smaller contractors, the financial barrier may limit adoption.

Finally, coordination between stakeholders can be difficult. Architects, engineers, and contractors may each rely on different software workflows. Without clear data management strategies, confusion arises over which version of a file is current, leading to costly rework.

Top Benefits

- Identifies the gaps in using advanced digital tools effectively.

- Helps contractors prepare for training and software needs.

- Improves risk awareness when adopting multi-platform workflows.

Best Practices for Overcoming Integration Challenges

- Standardize file formats and version control across all teams.

- Provide regular training and certifications for staff.

- Budget for technology adoption as a long-term investment.

Recognizing the challenges upfront allows contractors to put safeguards in place and maximize the value of GIS, BIM, and CAD integration.

StruxHub

Discover how StruxHub can revolutionize your construction management. Contact us today!

How StruxHub Helps Contractors Leverage GIS, BIM, and CAD Together

Even with advanced digital tools in play, coordination remains the biggest challenge on large construction projects. This is where StruxHub comes in—offering a platform to centralize communication, documentation, and field coordination.

StruxHub doesn’t replace GIS, BIM, or CAD—it complements them by serving as the connective tissue between field teams and digital models. Superintendents can link GIS maps, BIM files, and CAD drawings into StruxHub dashboards, making information accessible on mobile devices for crews in the field.

The platform also helps manage workflows. Deliveries, inspections, and daily reports can be tied to specific BIM components or GIS layers, ensuring that data isn’t just stored but actively used in decision-making. For contractors managing massive jobsites, this integration translates into fewer miscommunications, faster approvals, and stronger accountability.

Top Benefits

- Bridges the gap between design models and field execution.

- Provides mobile access to GIS, BIM, and CAD data onsite.

- Enhances collaboration across contractors, engineers, and owners.

Best Practices for Using StruxHub with GIS, BIM, and CAD

- Link digital models directly to jobsite tasks and schedules.

- Train field crews on accessing data through mobile dashboards.

- Use StruxHub to track updates and ensure teams work from the latest files.

By centralizing communication and access, StruxHub ensures GIS, BIM, and CAD aren’t siloed systems but part of a unified approach to construction management.

StruxHub

Experience the power of StruxHub today and witness firsthand how it can revolutionize your construction operations.

FAQ

What is the main difference between GIS, BIM, and CAD in construction?

The main difference lies in scope and purpose. GIS focuses on geographic and environmental context, BIM focuses on the design and management of the building itself, and CAD provides the precise drawings needed for components and assemblies.

GIS answers questions like, Where should we build, and how does this project fit into the surrounding landscape? It provides insights into soil conditions, floodplains, existing utility lines, and transportation networks. This makes it especially useful in early planning stages or for infrastructure-heavy projects.

BIM, in contrast, asks How will we build this facility, and how will it operate throughout its lifecycle? BIM creates a 3D digital model rich with data about materials, costs, scheduling, and even maintenance. It improves collaboration between architects, engineers, and contractors by offering a shared, dynamic model rather than static drawings.

CAD supports both by answering What are the exact specifications of each component? Engineers use CAD to produce detailed 2D or 3D drawings for fabrication and installation. While it lacks the context of GIS or the intelligence of BIM, CAD remains essential for precision.

Together, these three tools form a complementary ecosystem. GIS provides context, BIM provides coordination, and CAD provides precision. When used together, they reduce errors, improve planning, and deliver better project outcomes.

How do contractors integrate GIS, BIM, and CAD in real-world projects?

Integration typically happens through digital platforms that allow data to flow between systems. For example, GIS data about site topography can be imported into BIM models, giving designers a better understanding of how the building will interact with the environment. Similarly, CAD drawings can be embedded into BIM models for precision while still maintaining the broader context.

Contractors often establish data exchange standards early in the project. This ensures that CAD files, BIM models, and GIS maps use compatible formats and version control. Without these standards, integration can cause misalignments or lost details when transferring files.

Onsite, integration becomes even more important. Field crews may use tablets or mobile apps to access GIS maps for utility locations, BIM models for installation sequencing, and CAD drawings for exact measurements—all from the same dashboard. By connecting these tools, contractors reduce the risk of miscommunication between office and field teams.

Digital twins are another advancement. By combining GIS, BIM, and CAD into a single virtual model, contractors can simulate construction sequences, logistics, and operations before they happen. This predictive capability saves time and money while minimizing risks.

In practice, integration requires collaboration, technology investment, and training. But the payoff is significant: fewer clashes, more efficient workflows, and stronger alignment across the entire construction team.

What are the biggest challenges in adopting GIS, BIM, and CAD together?

One of the biggest challenges is interoperability. Not all software platforms communicate seamlessly, so contractors often face issues converting file formats. This can lead to data loss, errors, or duplication. Establishing interoperability standards is critical to prevent these problems.

Training is another hurdle. While CAD is widely understood, fewer professionals are fully trained in BIM and GIS. Contractors must invest in upskilling their teams to unlock the full potential of these tools. Without training, technology adoption often stalls or is misused.

Cost is also a challenge. Licensing software, purchasing powerful hardware, and hiring specialists can be expensive, especially for smaller contractors. Some firms hesitate to adopt all three technologies because of budget concerns, even though the long-term benefits outweigh the upfront costs.

Finally, cultural resistance can slow adoption. Teams used to traditional 2D drawings may resist switching to 3D BIM workflows or data-heavy GIS systems. Overcoming this requires leadership buy-in and clear communication about how the tools improve efficiency and reduce risk.

Despite these challenges, contractors who successfully integrate GIS, BIM, and CAD gain a competitive advantage. They deliver projects faster, with fewer errors, and with better lifecycle value.

How does BIM differ from CAD in terms of project outcomes?

The difference between BIM and CAD lies in intelligence versus precision. CAD is focused on exact geometry—it produces accurate 2D drawings or 3D models that define how a component is built. BIM goes further by embedding data into the model. A BIM object isn’t just a line or a shape; it contains information about material type, cost, manufacturer, performance, and maintenance requirements.

In terms of project outcomes, CAD ensures precision at the component level, while BIM ensures collaboration and efficiency at the project level. For example, CAD can provide the exact dimensions of a steel beam, but BIM will show how that beam interacts with ductwork, electrical conduits, and fire protection systems. This reduces clashes and prevents costly rework onsite.

BIM also supports lifecycle management. Once construction is complete, BIM models can be handed over to facility managers, who use them for operations and maintenance. CAD doesn’t provide this functionality—it ends at design.

In short, CAD is critical for detail, but BIM transforms detail into intelligence. Together, they ensure accuracy and collaboration, leading to smoother workflows and better outcomes.

How can StruxHub improve workflows involving GIS, BIM, and CAD?

StruxHub helps contractors bridge the gap between these powerful tools and day-to-day field execution. While GIS, BIM, and CAD each generate valuable data, that information often becomes siloed. StruxHub centralizes access, allowing superintendents and crews to view GIS maps, BIM models, and CAD drawings in one platform.

For example, StruxHub can link GIS utility maps to daily site reports, ensuring crews know exactly where underground lines are located. BIM models can be tied to inspection checklists, making it easy to confirm that installations meet design specifications. CAD drawings can be uploaded and referenced in real time, reducing the risk of crews working from outdated files.

StruxHub also adds accountability. By tying deliveries, safety inspections, and crew schedules to GIS and BIM models, project managers gain a real-time view of progress. This not only improves efficiency but also provides owners with transparent reporting.

The result is a seamless workflow where digital design tools and field operations are fully aligned. StruxHub doesn’t replace GIS, BIM, or CAD—it ensures they work together effectively to deliver better construction outcomes.

StruxHub

Discover how StruxHub can revolutionize your construction management. Contact us today!

Pillar Articles Links:

Best Guide to Construction Logistics Plans (CLPs): What Owners Want to See Before Work Starts

Best Construction Scheduling Software for General Contractors and Superintendents