Everything Superintendents and Contractors Need to Know About GIS Site Utilization Planning for Large Construction Projects

Table of Contents:

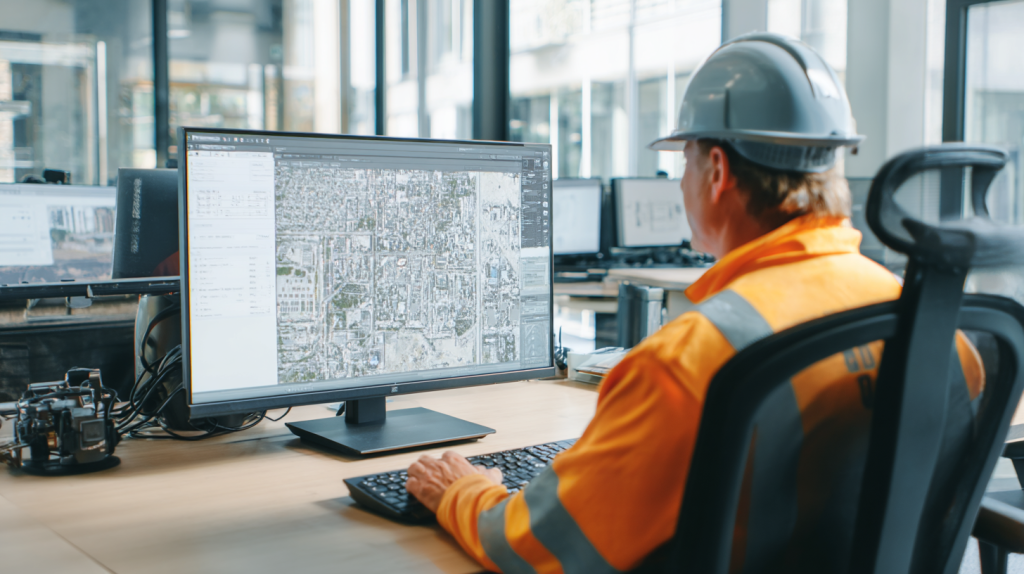

A Geographic Information System (GIS) is no longer just a tool for mapping—it’s becoming one of the most powerful technologies for planning, managing, and visualizing complex construction sites. For large-scale projects with multiple trades, heavy equipment, and tight schedules, GIS-based Site Utilization Planning (SUP) offers a data-driven way to improve coordination, reduce risk, and enhance productivity.

In traditional planning, site layouts are drawn manually using CAD or BIM tools. While effective, these drawings can quickly become outdated as conditions change. GIS takes this to the next level by integrating real-time geographic data—such as topography, soil stability, access routes, and utilities—into the planning process. This helps contractors and superintendents make more informed decisions about where to place cranes, storage zones, trailers, and traffic routes.

For superintendents, GIS-based SUPs provide a live, interactive map that can be updated and shared instantly with crews, project managers, and owners. It transforms jobsite planning from a static exercise into a dynamic management system—connecting field conditions with logistics, scheduling, and safety planning.

In this article, we’ll explore how GIS transforms Site Utilization Planning, what features it includes, and how both superintendents and contractors can use it to streamline coordination across large construction projects. You’ll also learn how digital platforms like StruxHub bring GIS data directly into field workflows, creating a smarter, safer, and more connected jobsite.

Why GIS Is Changing How Large Construction Sites Are Planned

In large-scale construction, traditional 2D planning tools can only show part of the picture. GIS fills in the gaps by integrating location intelligence—data tied to real-world geography—to help teams make better spatial and logistical decisions.

A GIS-based Site Utilization Plan combines aerial imagery, topographic maps, and underground utility data to give contractors a true “big picture” view of their site. This allows superintendents to plan more accurately, ensuring crane pads are built on stable ground, access roads follow safe gradients, and laydown areas avoid drainage zones.

Because GIS is dynamic, it also improves collaboration. Teams can layer safety zones, equipment routes, and construction phases onto a single, interactive map that updates in real time. These live visuals allow faster adjustments when field conditions change, such as rerouting a haul road after unexpected weather.

Top Benefits

- Provides accurate, data-rich mapping for real-world decision-making.

- Enhances safety and logistics coordination for large sites.

- Enables real-time updates that keep plans aligned with field conditions.

Best Practices

- Integrate GIS data with drone imagery and survey maps.

- Use GIS layers to track changes in terrain and infrastructure.

- Update and share the plan daily as site conditions evolve.

Q&A Mini Section

Q: Why is GIS especially useful for large construction projects?

A: Because large sites involve complex logistics that benefit from precise, data-driven spatial coordination.

Q: How does GIS improve accuracy over standard drawings?

A: It ties every element to real geographic coordinates, ensuring plans match actual site conditions.

Q: Is GIS compatible with BIM and CAD?

A: Yes—GIS integrates with both to create a comprehensive digital twin of the project site.

GIS brings a new level of intelligence to construction planning, giving teams the context they need to build smarter and safer.

What Information Does a GIS-Based Site Utilization Plan Include?

A GIS-based Site Utilization Plan contains all the standard elements of a traditional SUP—such as laydown zones, crane routes, temporary facilities, and safety areas—but it adds layers of geographic and environmental data that make the plan far more powerful.

Key GIS layers may include:

- Topography and contour mapping for elevation and grading analysis.

- Utility maps showing underground and overhead infrastructure.

- Soil and drainage data to guide heavy equipment placement.

- Traffic flow and access routes for vehicles and personnel.

- Environmental overlays highlighting protected areas or flood zones.

This layered data ensures that every placement—whether it’s a crane base or material storage area—is based on measurable site conditions, not assumptions. It also helps superintendents visualize how the site will evolve over time by linking logistics to project phasing and scheduling data.

Top Benefits

- Combines safety, logistics, and environmental factors in one plan.

- Reduces rework caused by inaccurate or incomplete information.

- Supports compliance with environmental and permitting standards.

Best Practices

- Collaborate with GIS specialists during preconstruction.

- Validate data sources before integrating them into the plan.

- Keep all map layers organized and version-controlled.

Q&A Mini Section

Q: What’s the difference between a standard SUP and a GIS-based one?

A: A GIS-based plan includes geospatial data and real-time updates, while a standard SUP is static and manually updated.

Q: Do GIS plans require special training to interpret?

A: Some, but modern tools like StruxHub make them user-friendly for superintendents and field staff.

Q: How often should GIS maps be updated?

A: Ideally weekly or whenever site conditions—such as elevation, access, or weather—change.

A GIS-based SUP gives project leaders a complete, data-backed understanding of the site, allowing smarter planning and faster adjustments.

How Do Superintendents Use GIS for Daily Jobsite Coordination?

Superintendents are the frontline users of GIS-enabled Site Utilization Plans. They rely on these maps to make real-time decisions about space management, equipment movement, and crew safety.

On a large jobsite, superintendents can use GIS to track material deliveries, identify bottlenecks, and confirm that crane and vehicle routes remain clear. Because GIS links directly to GPS data, they can even view live positions of equipment and trucks relative to planned paths. This reduces accidents, improves sequencing, and helps crews stay organized throughout the day.

GIS also strengthens communication between the field and office. Superintendents can mark changes—like a rerouted path or closed zone—on the digital map, and that update instantly syncs to every user on the platform. This keeps foremen, subcontractors, and project managers fully aligned.

Top Benefits

- Gives superintendents real-time visibility into site logistics.

- Reduces coordination errors by aligning field and office teams.

- Supports data-driven decision-making on safety and workflow.

Best Practices

- Use mobile GIS tools to update layouts directly from the field.

- Sync GIS plans with daily reports and inspections.

- Review GIS data during coordination and safety meetings.

Q&A Mini Section

Q: How do GIS tools help during daily site walks?

A: Superintendents can verify that equipment and crews are operating within designated zones and identify layout issues immediately.

Q: Can GIS track material and equipment movement?

A: Yes—GPS integration lets teams monitor routes and delivery progress in real time.

Q: What’s the biggest advantage for field teams?

A: Clear visibility—everyone knows where to go, what’s active, and what areas to avoid.

By bringing live data to the field, GIS gives superintendents the insight they need to manage large sites with precision and confidence.

How Does GIS Improve Collaboration Between Contractors and Field Teams?

On large construction projects, coordination between contractors, superintendents, and field crews can be one of the biggest challenges. A GIS-based Site Utilization Plan helps solve this problem by creating a shared, data-driven workspace that all teams can access in real time.

When everyone—from the general contractor to trade foremen—works from the same digital map, miscommunication drops dramatically. Contractors can see exactly where crews are working, where deliveries are scheduled, and how traffic routes are being used. Any change, such as relocating a laydown area or rerouting crane paths, is updated instantly and visible to everyone.

This transparency makes planning meetings faster and more effective. Instead of reviewing static PDFs, teams can use live GIS dashboards to visualize the current site layout and discuss upcoming changes. This approach improves trust, accountability, and coordination across all stakeholders—reducing costly rework and downtime.

Top Benefits

- Aligns field and office teams with one real-time visual map.

- Reduces errors caused by outdated or conflicting information.

- Speeds up coordination meetings and decision-making.

Best Practices

- Use a centralized GIS platform accessible to all contractors.

- Standardize communication protocols for updates and approvals.

- Incorporate GIS visuals into weekly logistics and safety meetings.

Q&A Mini Section

Q: How does GIS reduce miscommunication between teams?

A: Because all updates happen in real time, everyone works from the same version of the plan—no mixed messages or outdated drawings.

Q: Can subcontractors access GIS maps directly?

A: Yes, with permission-based access, subcontractors can view or annotate site layouts relevant to their work zones.

Q: How does GIS improve owner visibility?

A: Owners can monitor live progress and logistics remotely, improving transparency and accountability.

A shared GIS platform turns coordination from a manual process into a digital ecosystem—keeping every stakeholder aligned and informed.

StruxHub

Experience the power of StruxHub today and witness firsthand how it can revolutionize your construction operations.

What Are the Biggest Challenges with GIS Site Utilization Planning?

While GIS technology offers tremendous benefits, its successful adoption comes with a few challenges. The first is data accuracy. GIS maps rely on accurate spatial and environmental data, and errors in source data—like outdated surveys or missing utility records—can cause planning mistakes. Contractors must ensure all inputs are verified and updated regularly.

The second challenge is training and accessibility. Many superintendents and field workers are still learning how to use GIS-based tools effectively. Without proper onboarding, teams may default back to outdated paper drawings or misinterpret digital layers.

Finally, integration can be a hurdle. Large projects often use multiple systems—BIM for building models, CAD for design layouts, and GIS for spatial data. If these systems don’t communicate seamlessly, valuable information can get lost between departments.

Despite these challenges, the benefits far outweigh the obstacles. As GIS becomes more intuitive and integrated with construction platforms like StruxHub, it’s rapidly becoming a standard tool rather than a luxury.

Top Benefits

- Identifies key considerations before implementing GIS.

- Encourages quality control and user training for better adoption.

- Helps teams plan integration with existing construction software.

Best Practices

- Validate all data sources before importing into GIS maps.

- Provide field training sessions for superintendents and crews.

- Choose integrated platforms that sync GIS with BIM and project management tools.

Q&A Mini Section

Q: What’s the most common mistake in GIS site planning?

A: Using outdated or incomplete survey data, which can lead to incorrect layout decisions.

Q: How can teams overcome the learning curve?

A: By starting small—introducing GIS gradually through site mapping, then expanding to logistics and safety planning.

Q: Is GIS integration costly?

A: The initial setup may require investment, but long-term efficiency and safety gains quickly offset the cost.

Understanding these challenges helps teams prepare for a smoother transition into GIS-based planning and ensures better long-term results.

Related Articles:

Best Guide to AI in Construction Project Management: How Smart Tools Are Improving Construction Site Productivity; AI

Best Guide to Geographic Information Systems (GIS) in Construction: How Location-Based Data Improves Construction Project Management

Best Guide to Smart Helmets in Construction: Enhancing Safety, Communication, and Site Efficiency

Best Construction Scheduling Software for General Contractors and Superintendents

Best Guide to Solar Farm Construction Management: Top Solar Construction Management Software for Tracking Projects, Deliveries, and Compliance

Best Guide to Creating a Construction Site Utilization Plan with GIS Mapping, AI, and Logistics Tools

How Does GIS Support Safety and Environmental Management on Construction Sites?

GIS isn’t just about layout efficiency—it’s a vital tool for enhancing safety and sustainability. By mapping risk zones and environmental features, GIS helps teams identify hazards and protect both workers and the surrounding environment.

For example, GIS can overlay environmental data such as flood plains, erosion zones, or protected wetlands directly onto the SUP. This prevents teams from staging equipment or storing materials in areas that could violate environmental regulations. GIS also supports stormwater management by mapping natural drainage patterns and runoff routes.

From a safety perspective, GIS enables proactive risk planning. Superintendents can mark exclusion zones, crane swing areas, and emergency access points on digital maps that update in real time. These visuals make it easier for crews to understand where they can work safely and how to respond in an emergency.

Top Benefits

- Improves hazard awareness and emergency preparedness.

- Ensures compliance with environmental and safety regulations.

- Promotes sustainable construction practices through better site management.

Best Practices

- Include environmental and safety data layers in all GIS site maps.

- Review GIS hazard zones during daily toolbox talks.

- Integrate GIS updates with safety reporting and inspection workflows.

Q&A Mini Section

Q: Can GIS predict potential environmental impacts?

A: Yes—by analyzing terrain, water flow, and vegetation data, it helps predict where construction could cause disruption.

Q: How does GIS improve safety awareness?

A: Crews can visualize live hazard maps and exclusion zones directly on mobile devices, increasing situational awareness.

Q: Does GIS help with regulatory compliance?

A: Absolutely—it documents spatial data used for permits, inspections, and safety audits.

GIS ensures safety and sustainability are built into the project from day one, not added as afterthoughts.

StruxHub

Discover how StruxHub can revolutionize your construction management. Contact us today!

How StruxHub Integrates GIS for Better Site Utilization Planning

While GIS provides powerful mapping and analysis capabilities, it becomes even more valuable when paired with StruxHub, which integrates those insights into everyday construction workflows.

StruxHub allows superintendents and contractors to manage GIS-based Site Utilization Plans in real time—combining logistics, safety, and communication into one collaborative platform. Through mobile access, teams can overlay GIS maps with delivery routes, material staging zones, or crane positions. Changes made in the field automatically sync across all users, eliminating delays and confusion.

StruxHub also links GIS data to daily reporting, scheduling, and inspection tools, creating a complete project management ecosystem. This helps decision-makers connect spatial data with performance metrics, ensuring plans are not only accurate but also actionable.

By integrating GIS and StruxHub, teams gain both visibility and control—seeing the site as it exists today while planning smarter for tomorrow.

Top Benefits

- Connects GIS data with real-time construction workflows.

- Enables field-based updates that instantly sync to all users.

- Provides a unified view of safety, logistics, and scheduling data.

Best Practices

- Use StruxHub as the main interface for GIS site management.

- Train crews to annotate and flag updates directly in the platform.

- Leverage GIS data for post-project reporting and analysis.

Q&A Mini Section

Q: How does StruxHub make GIS more usable in the field?

A: It translates complex GIS layers into simple, interactive visuals accessible to any field user.

Q: Can StruxHub replace standalone GIS software?

A: It complements it—combining GIS data with logistics, communication, and scheduling tools for practical field use.

Q: How does StruxHub improve coordination using GIS?

A: It keeps every stakeholder aligned with real-time site visibility, updates, and data sharing.

By integrating GIS into the daily workflow, StruxHub bridges the gap between advanced mapping technology and practical construction management.

FAQ

What is GIS Site Utilization Planning and how is it different from traditional planning methods?

GIS Site Utilization Planning is the process of using Geographic Information Systems to map, analyze, and manage how space is used on a construction site. Unlike traditional 2D or CAD-based planning, GIS integrates real-world geographic data—such as elevation, soil type, drainage, and utility locations—into the planning process. This gives contractors a deeper understanding of the physical environment before breaking ground.

Traditional site plans are static; they show where things should go but not how conditions may affect those decisions. GIS brings context. It allows planners to visualize the site in layers, including terrain, environmental boundaries, and nearby infrastructure. For example, it can show where water accumulates during rain, helping teams avoid placing laydown areas in flood-prone zones.

The biggest advantage of GIS planning is accuracy and adaptability. It can be updated in real time as construction progresses, ensuring that decisions always reflect current site conditions. By merging geospatial analysis with construction logistics, GIS transforms site planning from a design exercise into an intelligent, data-driven workflow that enhances both safety and efficiency.

How do superintendents use GIS technology on the jobsite?

Superintendents use GIS technology as a real-time command center for managing logistics, safety, and field coordination. Through mobile GIS dashboards or platforms like StruxHub, they can access detailed maps that show the live positions of cranes, trucks, laydown areas, and work zones. This helps them coordinate daily activities more efficiently and make quick adjustments when issues arise.

For example, if a delivery truck reports delays, the superintendent can check GIS data to reroute other deliveries or adjust material staging areas to prevent congestion. If unexpected weather affects ground stability, GIS layers can help identify alternative zones for heavy equipment.

GIS also improves communication. Superintendents can mark updates directly on digital maps—such as a new hazard area or a temporary closure—and share them instantly with crews and subcontractors. These updates ensure everyone works from the same plan, reducing miscommunication and improving safety awareness.

In essence, GIS turns the jobsite into an interactive ecosystem. It gives superintendents the visibility and control needed to manage complex operations with precision, keeping projects on schedule and crews safe.

What types of data are included in a GIS-based Site Utilization Plan?

A GIS-based Site Utilization Plan includes both traditional construction layout data and geospatial environmental information. Together, these data layers create a multidimensional view of the jobsite.

Typical GIS data layers include:

- Topographic contours showing elevation and slope.

- Soil composition and drainage for foundation and equipment planning.

- Utility maps showing existing underground or overhead lines.

- Environmental overlays such as wetlands, flood zones, and protected habitats.

- Logistics data like road access, crane paths, and laydown areas.

By combining this data, planners can make informed decisions about where to position equipment, how to design traffic flow, and where to stage materials safely. GIS also supports scheduling by linking specific map areas to construction phases, showing how the site layout will evolve over time.

This data-driven approach reduces uncertainty. Rather than reacting to problems like unstable soil or blocked access, teams can anticipate them and plan accordingly. The result is a site plan grounded in real-world data—one that supports smarter, safer, and more sustainable construction.

How does GIS enhance safety and risk management on large projects?

GIS is one of the most powerful tools for improving jobsite safety and risk management because it provides visibility into hazards before they become incidents. By mapping the site in layers, contractors can identify risk zones—such as steep slopes, high-traffic areas, or restricted access zones—and proactively design around them.

For instance, GIS allows safety managers to visualize crane swing zones, truck routes, and pedestrian walkways simultaneously. Overlapping areas can be flagged as potential hazards and corrected before work begins. GIS also helps track temporary safety elements like fencing, signage, and egress points to ensure compliance with safety regulations.

In addition to physical safety, GIS aids in environmental risk management. It helps teams map stormwater runoff, erosion risks, and environmentally sensitive zones, ensuring the project adheres to local and federal environmental standards.

By integrating GIS into daily safety meetings or toolbox talks, superintendents can show crews exactly where dangers exist using live maps. This visual clarity enhances awareness and helps foster a proactive safety culture. Ultimately, GIS doesn’t just record risks—it predicts and helps prevent them.

How does StruxHub make GIS data more accessible and actionable for construction teams?

StruxHub bridges the gap between GIS data and day-to-day construction management by translating complex geospatial information into a practical, easy-to-use field tool. Instead of requiring specialized GIS software or training, StruxHub brings all that data into a familiar interface designed for superintendents, project managers, and field crews.

Within StruxHub, users can overlay GIS maps with live logistics data—like delivery schedules, equipment placement, and work zone boundaries. When changes occur, such as shifting a crane path or closing a road, those updates are reflected immediately across the platform and shared with all team members.

The system also integrates with other key workflows, including safety reporting, daily logs, and scheduling, ensuring that GIS data directly informs decision-making. Superintendents can annotate the digital plan, attach photos, and communicate updates in real time, eliminating confusion and improving accountability.

By combining GIS precision with collaborative project management, StruxHub turns static maps into living coordination systems. It gives construction teams not only visibility but also the power to act on it—keeping projects safer, faster, and more connected than ever before.