How Smart Helmets Are Transforming Construction Site Safety

Table of Contents:

Construction is one of the most dangerous industries in the world — with fall hazards, struck-by incidents, and environmental risks present on nearly every job. While traditional safety gear has helped reduce injuries, a new generation of technology is pushing safety to the next level: smart helmets.

These high-tech hard hats go beyond basic head protection. They include features like built-in sensors, real-time environmental monitoring, GPS tracking, video capture, and voice-activated communication — all designed to help workers avoid hazards before accidents happen. By blending wearable tech with practical field tools, smart helmets are transforming how safety is managed, reported, and enforced across construction sites.

In this guide, we’ll explore how smart helmets are being used to prevent incidents, improve situational awareness, and support faster response times. We’ll also look at the challenges, costs, and what project leaders need to know to adopt them successfully — with or without hardware integration.

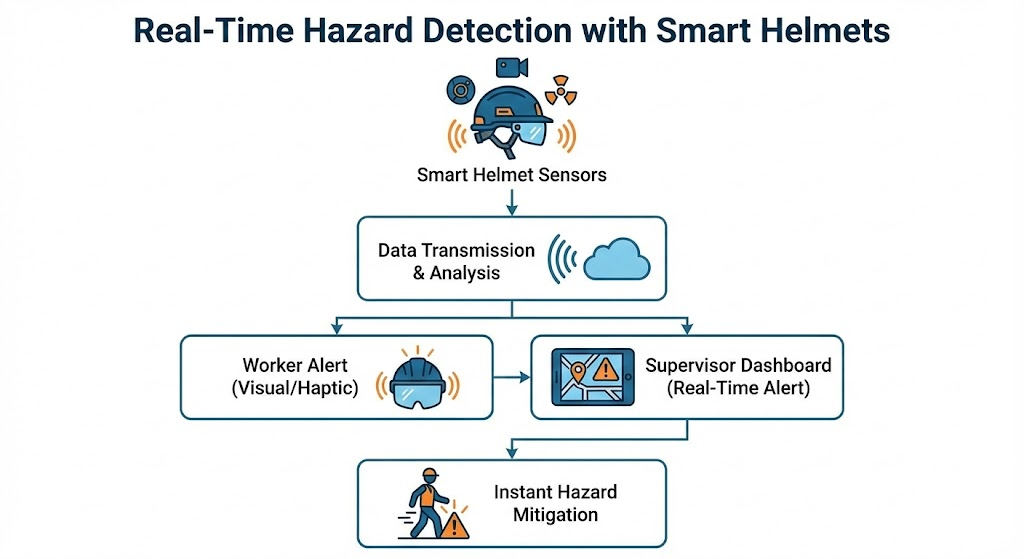

Real-Time Hazard Detection Is Changing the Game

One of the biggest breakthroughs in smart helmet technology is real-time environmental monitoring. These helmets can detect gas leaks, excessive noise levels, temperature spikes, and even proximity to moving equipment — all while alerting the wearer instantly through audio, visual, or vibration cues. This transforms the helmet from a passive layer of protection into a proactive alert system.

It’s especially useful in enclosed or complex spaces where hazards aren’t always visible — like crawl spaces, electrical rooms, or mechanical chases. Workers can receive alerts before entering a dangerous zone or stop work immediately if conditions change unexpectedly.

For safety managers, these features mean faster response times and better incident prevention. And for workers, it builds trust that their PPE is looking out for them, not just checking a compliance box.

Problems

- Many hazards (heat, gas, noise) aren’t detectable without sensors

- Workers often lack awareness of changing environmental risks

- Delayed detection leads to higher risk of serious injury

Solutions

- Smart helmets monitor site conditions continuously and alert wearers instantly

- Field teams gain awareness of invisible or rapidly changing hazards

- Early detection reduces incidents and supports proactive decision-making

Best Practices

- Deploy smart helmets in high-risk zones or enclosed work areas

- Use alerts to trigger workflow pauses or supervisor notifications

- Integrate sensor data into weekly safety reports or site reviews

When seconds matter, real-time alerts make all the difference. Smart helmets help stop incidents before they start — one signal at a time.

Improving Communication in Noisy, Fast-Moving Environments

Jobsite communication has always been a challenge — between the noise of equipment, scattered teams, and the need for hands-on focus, messages often get lost or delayed. Smart helmets help solve that by enabling hands-free, voice-activated communication, allowing workers to stay connected without stopping what they’re doing.

Some helmets include bone-conduction audio or noise-canceling mics, making them usable in loud environments where radios struggle. Others support real-time voice translation or streaming to supervisors off-site. This tightens the communication loop, improves coordination, and cuts down on missteps caused by poor or delayed messaging.

This is especially valuable during safety walkthroughs, crane lifts, or equipment installations — where coordination is key and split-second decisions count.

Problems

- Traditional radios and phones are often ineffective in loud or chaotic zones

- Delayed communication increases risk during lifts, tie-ins, or walkthroughs

- Field workers can’t easily document or report issues without stopping work

Solutions

- Voice-activated smart helmets allow seamless communication without distraction

- Live audio/video enables supervisors to support or intervene remotely

- Speech-to-text logs offer documented proof of instructions and alerts

Best Practices

- Equip foremen or key crew members with smart comms for better coverage

- Use helmet audio logs as part of toolbox talks or post-incident reviews

- Link communication protocols to safety workflows for faster follow-up

Clearer communication means safer jobs. With smart helmet comms, workers stay focused, informed, and connected — no matter how loud the job gets.

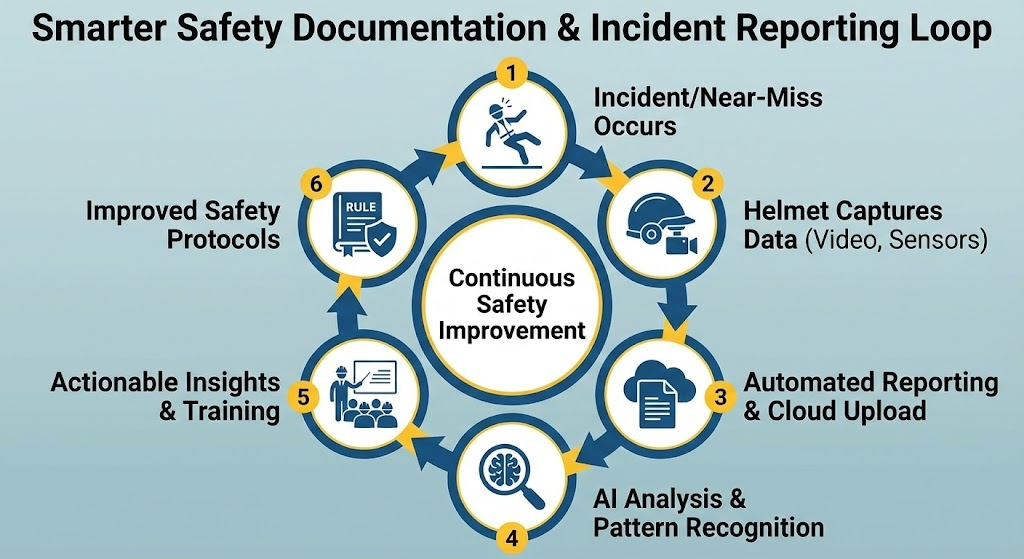

Smarter Safety Documentation and Incident Reporting

Safety documentation has always been a headache — clipboards, paperwork, and scattered digital files slow down reporting and make incident investigations harder than they should be. Smart helmets flip that script by enabling automatic photo, video, and voice documentation at the point of work.

Imagine a worker spotting a frayed wire or unsecured trench plate. Instead of flagging it later, they simply capture a voice memo and photo through the helmet — which can then be uploaded and tied to a safety issue log. This kind of real-time reporting improves accuracy, accountability, and the speed at which problems get fixed.

It also helps build a culture of documentation, where workers feel empowered to report, and supervisors have the visibility to act — even if they’re not physically present.

Problems

- Manual reporting delays slow down safety response

- Documentation is inconsistent, scattered, or gets lost in transit

- Incident investigations lack clear visual records or timelines

Solutions

- Smart helmets support photo, video, and audio capture during work

- Reports can be created instantly and stored securely

- Data helps improve safety audits, compliance, and post-incident analysis

Best Practices

- Use smart helmet footage as part of your regular safety audit process

- Log minor observations before they become major problems

- Store visual documentation in a centralized platform like StruxHub

Better documentation doesn’t just protect your crew — it protects your company. Smart helmets make it faster and easier to stay compliant, transparent, and ahead of safety issues.

Empowering Workers with Situational Awareness

The best safety systems aren’t just protective — they’re empowering. One of the biggest benefits of smart helmets is how they give workers greater situational awareness on the jobsite. With built-in alerts, field data access, and real-time visibility, workers no longer have to rely solely on memory, guesswork, or waiting for supervisor direction.

This matters most in fast-changing environments like concrete pours, active lifts, or complex retrofits where conditions can shift by the hour. By receiving immediate visual or audio cues from their smart helmet — like gas alerts, temperature spikes, or proximity warnings — workers can make smarter decisions faster.

Beyond risk prevention, smart helmets help crews understand more about the site itself. With AR displays or model overlays, they can “see” what’s behind walls, above ceilings, or beneath slabs — reducing guesswork and improving installation accuracy.

Problems

- Workers often lack real-time context about hidden risks or changing conditions

- Safety awareness varies across crews depending on training or experience

- Field teams rely on static drawings or verbal instructions in dynamic environments

Solutions

- Smart helmets provide live cues and overlays that enhance decision-making

- Real-time alerts support confident, fast reactions to on-site hazards

- More informed workers make fewer mistakes and require less rework

Best Practices

- Use helmet-enabled overlays to visualize MEP clashes or congested areas

- Assign helmet-equipped crew to complex or high-risk tasks

- Include situational training in new worker onboarding using helmet examples

When workers feel informed and supported, they stay safer — and the quality of their work improves. Smart helmets help put that knowledge right where it’s needed most: on their heads, in the moment.

Limitations and Learning Curves of Smart Helmet Safety Features

As with any new technology, smart helmets come with real-world challenges — and they aren’t a perfect fit for every site or crew. It’s important for construction leaders to understand these limitations before rolling out helmets across the board.

The most common concerns include cost, weight, battery life, crew adoption, and data overload. Some helmets are bulky or uncomfortable for all-day wear, and battery performance can drop in extreme weather. Without clear training, workers may struggle to use features or distrust the tech entirely.

Another issue is workflow integration. If smart helmet data isn’t linked to your project system — or if supervisors don’t know what to do with the data — the value quickly fades. That’s why leadership buy-in, planning, and feedback loops are critical.

Problems

- High cost per unit limits widespread adoption

- Wearability and tech complexity can frustrate crews

- Collected data may sit unused without clear processes

Solutions

- Start small with pilot users on complex or safety-critical tasks

- Prioritize helmets with ergonomic designs and intuitive interfaces

- Plan workflows for how helmet data will be used and stored

Best Practices

- Involve your most tech-friendly supers or safety leads in the rollout

- Set weekly usage targets or milestones to track adoption

- Create quick-start guides or video tutorials for new users

Smart helmets have strong potential — but only when adopted with purpose and clarity. Leading contractors treat them like any safety asset: valuable, but only as effective as their training and use.

Related Articles:

The History and Evolution of Hard Hats to Smart Helmets in Construction

Best Guide to Construction Management Software

The Best Guide to Delivery Management Systems (DMS) for Commercial Construction

Superintendents: Effective Training Strategies for Construction Management Software Users

Why Smart Helmets Are the Future of Safety-First Construction

The construction industry is shifting — fast. Owners are demanding better visibility, projects are moving quicker, and safety expectations are higher than ever. In this new landscape, smart helmets offer something traditional PPE never could: a real-time connection between the worker, the jobsite, and the decisions that keep people safe.

Whether you’re operating a crane, walking a high-rise slab, or troubleshooting underground utilities, the ability to receive alerts, view models, or call for help instantly could mean the difference between progress and incident.

This isn’t just a trend — it’s part of a broader digital transformation sweeping through construction. Like drones and reality capture before them, smart helmets are becoming another layer of the connected jobsite — where safety is not just enforced but embedded into the workflow itself.

Problems

- Traditional safety gear can’t keep up with modern project speed and complexity

- Field-level decisions are often made without real-time data

- Safety success still depends too much on human oversight alone

Solutions

- Smart helmets give workers a second set of “eyes and ears” in dangerous conditions

- Tech-enabled PPE aligns with the broader push for digital site management

- Integration with other workflows creates a more proactive safety culture

Best Practices

- Include smart helmets in future site planning or project specs

- Use helmet-generated data in project KPIs and end-of-job reports

- Treat wearable safety tech as part of your competitive advantage

Safety is no longer just about avoiding fines or insurance claims — it’s about building a reputation for care, quality, and performance. Smart helmets are helping contractors deliver on all three.

How StruxHub Helps Teams Take Action on Field-Level Safety Data

Smart helmets are excellent at capturing data — footage, alerts, location, voice notes — but what happens after that matters just as much. StruxHub helps teams organize, act on, and communicate those insights, even without connecting directly to the devices.

Let’s say a helmet captures a photo of a hazard. That image can be uploaded to StruxHub and instantly logged as a safety issue. Supervisors can tag team members, assign a fix, and document the resolution — all from one centralized system. Or if a voice note describes a missing guardrail, it can be transcribed and linked to a punchlist item within minutes.

By centralizing documentation, action items, and reporting, StruxHub turns smart helmet data into structured, trackable progress. It doesn’t replace wearable tech — it amplifies it, ensuring field-level safety data doesn’t go to waste.

Problems Solved by StruxHub

- Field safety data is often disconnected from project tracking tools

- Teams struggle to follow up on observations or hazards reported through wearables

- Project managers lack visibility into day-to-day safety workflows

Why It Works

- StruxHub organizes and links field safety data to tasks, logs, and reports

- It supports cross-team visibility — even for crews not using smart helmets

- It enables fast response and clear accountability without hardware integration

Best Practices

- Create a workflow for uploading smart helmet documentation to StruxHub

- Use tagged issues and daily logs to drive project-wide safety reviews

- Build safety KPIs based on data logged and resolved in the system

With or without hardware, StruxHub helps construction teams build a culture of clarity, accountability, and safety. It’s not about the gear — it’s about what you do with the data it gives you.

Unlock the Full Potential of Your Construction Projects with StruxHub

StruxHub enhances efficiency and coordination across all project phases, providing a single source of truth that eliminates silos and fosters collaboration. Real-time updates, financial management tools, and seamless commvunication features ensure that all team members and stakeholders are aligned and informed, reducing the risk of errors and delays. With comprehensive solutions for document management, risk mitigation, and quality control, StruxHub maintains project integrity and safety, while mobile access and integration capabilities further enhance project flexibility and efficiency.

StruxHub’s Key Features and Benefits:

- Advanced Delivery Management: Automate and optimize your delivery schedules, ensuring materials arrive just in time, every time.

- Site Communication: Utilize georeferenced maps and instant messaging to keep every team member informed and aligned.

- Construction Materials Management: Track inventory levels and manage materials procurement with ease, reducing waste and avoiding project delays.

- Construction Safety & Inspection Workflows: Implement customizable mobile forms for conducting safety inspections and managing compliance documentation effortlessly.

- Short-Term Scheduling: Visualize project tasks with detailed floor plans, linking each activity to specific locations for better planning accuracy.

- Construction Resource Management: Efficiently allocate personnel and equipment, maximizing productivity and reducing idle time.

StruxHub’s Product Offering:

- StruxHub Deliveries: Simplifies the coordination of incoming deliveries, ensuring materials and equipment are precisely timed to project needs.

- StruxHub Logistics: Offers intelligent site logistics planning, from crane scheduling to space allocation, for smoother operations.

- StruxHub Safety: Elevates on-site safety standards with easy-to-use tools for inspections, permits, and incident reporting.

- StruxHub Scheduling: Enhances project timelines with intuitive scheduling tools that ensure tasks are completed efficiently and on time.

With StruxHub, construction companies can look forward to a streamlined, more efficient project execution that delivers on time and within budget. Embrace the power of innovation and take your construction projects to the next level.

Don’t miss out on the opportunity to optimize your construction management processes with StruxHub. Sign up for a free demo today. Let’s build smarter, together.

StruxHub

Experience the power of StruxHub today and witness firsthand how it can revolutionize your construction operations.

FAQ

Are smart helmets actually improving safety on construction sites?

Yes — smart helmets are proving to be a powerful tool in improving safety across construction sites, especially those with complex risks and fast-changing conditions. These helmets go far beyond standard PPE by incorporating real-time monitoring, hazard alerts, and live communication tools that give field workers more visibility and faster reaction time.

For example, a smart helmet with built-in gas sensors can alert a worker to dangerous air quality before entering a confined space. Others include GPS and location-based alerts, which can warn users when they approach dangerous zones, like crane swing areas or excavation pits. Some models also include fall detection or heat stress monitoring, helping supervisors identify problems before they become emergencies.

The result? Faster incident response, fewer near misses, and stronger overall safety culture. Teams using smart helmets are also capturing more accurate field data — like video documentation and voice memos — which help with post-incident reviews, safety training, and accountability.

While the tech is still evolving, there’s no doubt that smart helmets are actively reducing risk and enabling more proactive site safety strategies, especially when paired with supportive construction management software like StruxHub.

How do smart helmets work in noisy construction environments?

Smart helmets are designed specifically for loud, chaotic jobsite conditions. Many models use bone-conduction audio, noise-canceling microphones, and push-to-talk communication systems that function even in environments with jackhammers, lifts, or heavy equipment operating nearby.

This makes them especially useful for foremen, crane spotters, and safety leads who need to communicate clearly but can’t rely on hand signals or two-way radios. Because the communication is integrated into the helmet, workers can respond hands-free while keeping their focus on the task at hand — whether they’re tying rebar or managing an active lift.

In addition to verbal communication, many smart helmets can provide visual alerts or haptic (vibration) cues, so workers receive safety messages even when they can’t hear them. This multi-sensory approach helps reduce communication breakdowns and ensures critical messages don’t get lost in the noise.

By streamlining communication in noisy environments, smart helmets help field teams stay coordinated, respond faster, and avoid accidents caused by miscommunication.

Are smart helmets a good fit for small or mid-sized construction companies?

Yes — and in fact, many small to mid-sized firms are adopting smart helmets strategically, starting with select roles or projects where the return on investment is clearest. You don’t need to outfit your entire workforce to see the benefits.

For example, equipping just your superintendents, safety officers, or QA/QC leads with smart helmets can enhance site oversight, improve reporting accuracy, and streamline communication with project stakeholders. These helmets can also replace or reduce the need for separate radios, body cameras, or manual inspection reports — consolidating several tools into one.

Additionally, mid-sized contractors are using smart helmet footage to document jobsite conditions, reduce liability, and protect against claims. If a hazard is spotted or a delay occurs, you have visual records with timestamps — which can be invaluable during project closeout or legal disputes.

Even without full integration into your tech stack, smart helmets serve as a stepping stone toward modernizing your field operations. And when combined with platforms like StruxHub, you can turn helmet-collected data into structured tasks, logs, and updates without needing a full IT team to manage the process.

What safety data can smart helmets capture — and how should teams use it?

Smart helmets can capture a wide range of field-level safety data, including:

- Environmental conditions (e.g., gas levels, temperature, noise)

- Live video and photo documentation of site conditions

- Voice memos describing hazards or instructions

- Location tracking for movement monitoring or geofencing alerts

- Worker activity (e.g., falls, fatigue, long exposure in hazardous zones)

The challenge isn’t just capturing this data — it’s using it effectively. That’s where construction software like StruxHub comes in. Teams can upload helmet footage, transcribe voice notes, and log safety incidents into their daily reporting or safety workflows. This creates an audit trail that helps resolve issues faster, informs toolbox talks, and supports compliance reporting.

Using this data wisely allows companies to spot safety trends, improve crew training, and reduce recurring issues. It also gives safety managers a clearer picture of what’s happening across the site — especially on large or multi-phase builds where manual inspection isn’t always possible.

Do smart helmets integrate with construction management platforms like StruxHub?

Smart helmets don’t need to integrate directly with construction platforms to be useful. While some manufacturers offer API connectivity, most field teams use smart helmet data as standalone outputs — such as videos, photos, or alerts — which are then manually uploaded or linked to their project management system.

This is where platforms like StruxHub shine. Even without hardware integration, StruxHub helps teams organize smart helmet data in a meaningful way — by connecting it to RFIs, punchlists, safety logs, or daily reports. Field observations become actionable. Issues are assigned and tracked. And safety updates get shared across office and site without the confusion of siloed emails or folders.

So while StruxHub doesn’t directly connect to smart helmets, it plays a crucial role in turning raw field data into structured project action. That’s what keeps teams moving — and safer.