What’s the Difference Between a Site Utilization Plan and a Site Logistics Plan in Construction?

Table of Contents:

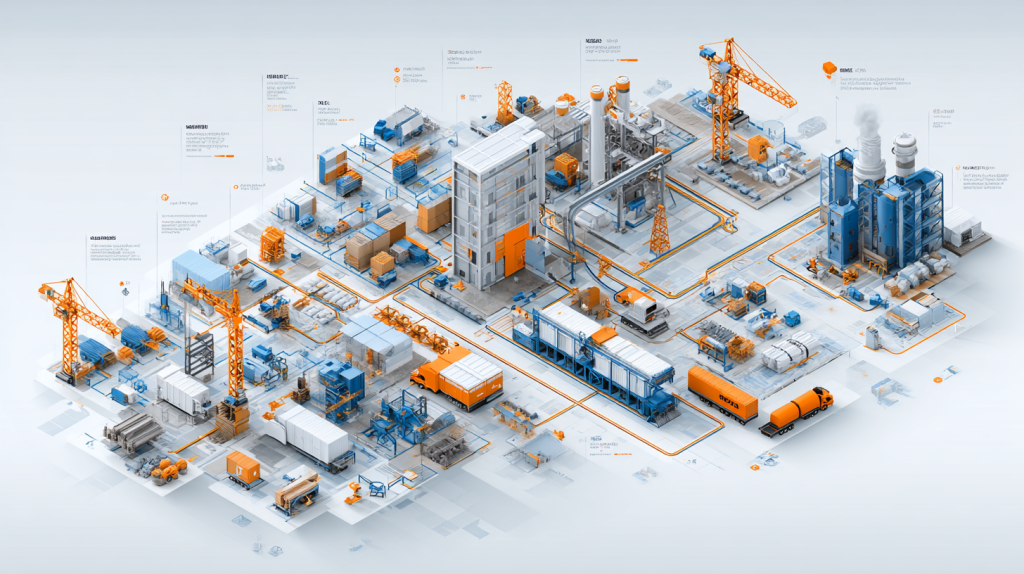

A Site Utilization Plan (SUP) is one of the most critical, yet often misunderstood, documents in construction project management. It is the master blueprint for how every square foot of a jobsite will be organized, accessed, and managed throughout the project lifecycle. From laydown areas and crane swing zones to pedestrian walkways and emergency routes, the SUP establishes the physical foundation for safety, efficiency, and coordination.

The primary purpose of a Site Utilization Plan is to optimize space and workflow—especially on crowded or complex sites where multiple trades, deliveries, and pieces of equipment compete for limited room. A well-designed SUP helps superintendents and project managers visualize the site layout before mobilization, anticipate potential conflicts, and plan logistics that minimize delays or hazards.

Unlike a project schedule, which dictates when tasks occur, the SUP focuses on where and how they take place. It’s both a safety document and an operational map, ensuring that materials, crews, and equipment move smoothly without interfering with one another.

In this article, we’ll explore why Site Utilization Plans are so essential, what they include, and how they evolve throughout a project. You’ll also learn how digital tools like StruxHub and GIS mapping are transforming how these plans are created, updated, and shared. Whether you’re an owner, superintendent, or contractor, understanding the purpose of a Site Utilization Plan can make the difference between a well-coordinated project and a chaotic jobsite.

Why Every Construction Project Needs a Site Utilization Plan

Every successful construction project starts with a plan—not just for scheduling or budgeting, but for how space itself will be used. A Site Utilization Plan provides that foundation, ensuring that the physical layout of the jobsite supports safe and efficient operations.

Without a SUP, even the most organized teams can experience confusion, traffic congestion, and safety hazards. Equipment may block access routes, materials pile up in unsafe zones, and deliveries interfere with ongoing work. The SUP prevents these issues by mapping out staging areas, routes, and clearances ahead of time, creating order from potential chaos.

For owners, the SUP also provides assurance that contractors are thinking strategically about safety and logistics. For superintendents, it’s a daily reference point for managing manpower, deliveries, and site sequencing.

Top Benefits

- Establishes a clear spatial strategy before construction begins.

- Prevents congestion, bottlenecks, and unsafe work conditions.

- Improves communication among all project stakeholders.

Best Practices

- Develop the SUP during preconstruction with input from field teams.

- Review and revise the plan as project phases change.

- Use color-coded layouts to distinguish between trades and zones.

Q&A Mini Section

Q: Who typically creates the Site Utilization Plan?

A: The general contractor or construction manager usually develops it during preconstruction in collaboration with engineers and field supervisors.

Q: How does a SUP differ from a Site Logistics Plan?

A: The SUP focuses on overall layout and strategy, while the logistics plan details daily operations and deliveries.

Q: When should the SUP be updated?

A: Updates should occur whenever major milestones are reached or when new structures, cranes, or temporary facilities are added.

A thoughtful SUP sets the tone for the entire project, ensuring that efficiency and safety are built into the site from day one.

What Information Should a Site Utilization Plan Include?

A strong Site Utilization Plan is more than just a drawing—it’s a visual coordination tool that combines safety, logistics, and operational strategy. At a minimum, the SUP should show major components like crane locations, laydown areas, access roads, storage zones, and pedestrian walkways.

Other essential elements include site boundaries, temporary structures, fencing, gates, signage, emergency routes, and utility connections. The plan should clearly identify restricted areas, waste management zones, and environmental protection measures such as silt fencing or drainage controls. For multi-phase projects, the SUP may include several versions—each corresponding to a specific stage of construction.

The goal is clarity. Every stakeholder, from delivery drivers to subcontractor foremen, should be able to understand the plan at a glance. Color coding, labeling, and layering by phase or trade help make the document intuitive and easy to follow.

Top Benefits

- Provides a comprehensive visual guide to site organization.

- Enhances safety by clearly marking restricted and hazard areas.

- Supports permitting and regulatory compliance documentation.

Best Practices

- Include scale references and north orientation for accuracy.

- Use distinct color coding for temporary vs. permanent elements.

- Verify accuracy through field walks before finalizing.

Q&A Mini Section

Q: Should the SUP include future work areas or only current ones?

A: It should include both current and planned zones to anticipate future space requirements and avoid rework.

Q: What tools are best for creating a SUP?

A: CAD, BIM, and GIS-based software are commonly used for accurate layering and easy updating.

Q: Is the SUP a required document for all construction projects?

A: While not always legally required, many owners and safety regulations now mandate it for large or complex jobs.

The more detailed and accurate your SUP, the smoother your operations will be—minimizing confusion, waste, and risk throughout the project.

StruxHub

Discover how StruxHub can revolutionize your construction management. Contact us today!

How Does a Site Utilization Plan Improve Safety and Efficiency?

Safety and efficiency are the two biggest benefits of a well-designed Site Utilization Plan. By mapping out movement, storage, and access in advance, teams can identify potential hazards and inefficiencies long before they appear onsite.

For example, if cranes and delivery trucks share the same route, the SUP will highlight that conflict before it becomes a safety issue. Similarly, if materials are stored too close to pedestrian paths, the plan will prompt relocation to reduce risk. A properly executed SUP ensures that heavy equipment, workers, and deliveries move through the site without interfering with one another.

Efficiency improves as well. Crews waste less time searching for materials or waiting for access, and deliveries can be scheduled with minimal overlap. The SUP also provides valuable data for scheduling—showing when certain areas of the site will be accessible or closed off.

Top Benefits

- Reduces jobsite accidents by separating workers and heavy equipment.

- Speeds up work by improving material access and workflow.

- Provides a visual reference for training and safety meetings.

Best Practices

- Review the SUP with crews during orientation and safety briefings.

- Include temporary signage that matches the SUP layout.

- Conduct field audits to verify compliance with the plan.

Q&A Mini Section

Q: How can a SUP reduce accidents onsite?

A: By defining traffic routes and exclusion zones that prevent workers and machinery from crossing paths.

Q: Does the SUP need to comply with OSHA standards?

A: Yes—especially for safety features like access control, fencing, and egress routes.

Q: Who enforces compliance with the SUP in the field?

A: The site superintendent and safety officer share responsibility for ensuring all teams follow the approved plan.

Related Articles:

Best Guide to AI in Construction Project Management: How Smart Tools Are Improving Construction Site Productivity; AI

Best Guide to Geographic Information Systems (GIS) in Construction: How Location-Based Data Improves Construction Project Management

Best Guide to Smart Helmets in Construction: Enhancing Safety, Communication, and Site Efficiency

How Do Site Utilization and Logistics Plans Work Together?

Although the Site Utilization Plan (SUP) and Site Logistics Plan (SLP) have distinct roles, they’re designed to work hand in hand. The SUP provides the strategic framework, while the SLP handles the tactical execution. Together, they ensure that the jobsite operates efficiently from day one to final handover.

The SUP establishes the long-term blueprint—where major structures, temporary facilities, and critical equipment will be located over time. The SLP then refines that framework to guide daily operations, such as delivery coordination, crew movement, and material sequencing. In other words, the SUP sets the “where,” and the SLP manages the “how.”

Coordination between these two documents is key. If the SUP isn’t updated to reflect real-world adjustments in the SLP, field activities can drift off plan. Likewise, without a clear SUP, logistics teams might make reactive decisions that disrupt site flow or safety. The most successful projects treat both as living documents that evolve together.

Top Benefits

- Aligns long-term strategy with daily operations.

- Ensures consistent communication between office and field teams.

- Prevents layout conflicts and improves site efficiency.

Best Practices

- Maintain both plans on a shared digital platform.

- Schedule weekly coordination meetings between planning and field teams.

- Update both documents simultaneously as site conditions change.

Q&A Mini Section

Q: How often should both plans be reviewed together?

A: At least once a week, or immediately following major layout or schedule changes.

Q: What happens if the SUP and SLP conflict?

A: The logistics plan must be adjusted to realign with the approved utilization framework.

Q: Who ensures synchronization between the two?

A: Typically, the project superintendent or logistics manager oversees coordination to maintain consistency.

When the SUP and SLP evolve in tandem, they create a seamless connection between planning and field execution—keeping the project on track both strategically and operationally.

What Common Mistakes Do Contractors Make When Developing SUPs and SLPs?

Even experienced contractors can fall into common pitfalls when developing site utilization and logistics plans. The most frequent mistake is treating the plans as static documents. Construction sites change rapidly, and failing to update layouts or routes as conditions evolve can lead to confusion, congestion, and inefficiency.

Another common error is designing plans in isolation. The SUP and SLP should always be developed collaboratively with input from field crews, safety officers, and subcontractors. When plans are created behind closed doors, they often overlook real-world site challenges—like crane swing paths, utility access, or delivery bottlenecks.

Finally, many teams overlook communication and accessibility. A well-drawn plan is useless if it’s locked away in an office computer. Field crews must be able to access the latest version digitally or through posted visuals onsite.

Top Benefits

- Helps contractors avoid costly rework and miscommunication.

- Increases safety and productivity through proactive coordination.

- Keeps planning documents aligned with real-world site dynamics.

Best Practices

- Treat both plans as living documents updated weekly.

- Involve all key trades and safety representatives in planning sessions.

- Use cloud-based tools for real-time version control.

Q&A Mini Section

Q: What’s the most common cause of SUP/SLP misalignment?

A: Delayed updates—when changes in field conditions aren’t reflected in both documents simultaneously.

Q: How can teams prevent layout conflicts between trades?

A: By holding regular coordination meetings using updated maps accessible to all parties.

Q: Why do printed plans often fail in large projects?

A: Because they can’t keep pace with daily site changes; digital platforms ensure accuracy and timeliness.

Avoiding these pitfalls turns planning documents from administrative chores into operational assets that directly improve jobsite performance.

Related Articles:

Best Construction Scheduling Software for General Contractors and Superintendents

Best Guide to Solar Farm Construction Management: Top Solar Construction Management Software for Tracking Projects, Deliveries, and Compliance

Best Guide to Creating a Construction Site Utilization Plan with GIS Mapping, AI, and Logistics Tools

How Does Technology Improve Site Utilization and Logistics Planning?

Technology has revolutionized how contractors plan and manage their sites. Digital mapping tools, drones, and Geographic Information Systems (GIS) make it possible to visualize, update, and share layouts in real time. With the right software, both the Site Utilization Plan (SUP) and the Site Logistics Plan (SLP) become dynamic management tools instead of static diagrams.

GIS-based systems, for example, allow teams to layer spatial data like terrain, utilities, and crane swing zones on top of live site imagery. Drones can capture daily progress and automatically update digital maps, while construction management platforms synchronize these updates across all users. This ensures that every trade, manager, and owner views the same, most recent information.

Automation also simplifies communication. Instead of distributing PDFs manually, modern platforms push instant updates to mobile devices. Superintendents can mark changes on tablets while walking the site, and office teams see those updates immediately.

Top Benefits

- Provides real-time visibility and data accuracy.

- Reduces miscommunication through automated updates.

- Integrates with project scheduling and reporting tools.

Best Practices

- Use drone and GIS mapping to update plans frequently.

- Train teams to navigate and annotate digital maps.

- Link logistics data directly to scheduling software for full coordination.

Q&A Mini Section

Q: Can GIS and BIM be used together in logistics planning?

A: Absolutely—BIM handles building details, while GIS manages spatial and environmental data, giving a complete project view.

Q: How do drones support site planning accuracy?

A: Drones provide updated aerial imagery that helps planners verify layouts and spot issues before they escalate.

Q: What’s the biggest advantage of using digital site planning tools?

A: Real-time updates and version control eliminate guesswork and prevent costly miscommunication.

Technology transforms planning from a static paper exercise into a responsive, collaborative system that adapts as quickly as the jobsite itself.

How StruxHub Simplifies Site Utilization and Logistics Coordination

StruxHub brings both Site Utilization Plans and Site Logistics Plans into a single, unified digital environment. Instead of managing separate files or relying on outdated PDFs, project teams can view, edit, and synchronize both documents directly within the platform—ensuring accuracy across all stakeholders.

With StruxHub, superintendents can update logistics details such as delivery routes, crane swing zones, and laydown areas from the field. These updates sync instantly with the overall utilization plan, keeping planners and owners informed in real time. The platform’s visual dashboards make it easy to see how changes affect the entire site, preventing conflicts before they occur.

StruxHub also improves communication between trades. Field teams can access the latest maps from mobile devices, while office teams receive notifications of any revisions. This transparency ensures everyone works from the same, most current information.

Top Benefits

- Centralizes SUP and SLP management into one real-time system.

- Prevents layout and logistics conflicts with instant updates.

- Improves collaboration between field, office, and owner teams.

Best Practices

- Use StruxHub as the single source of truth for all site plans.

- Integrate with GIS or BIM systems for maximum accuracy.

- Review site updates daily to ensure all trades stay aligned.

Q&A Mini Section

Q: How does StruxHub prevent outdated plans from circulating?

A: It automatically syncs updates across all user devices, ensuring everyone works from the latest version.

Q: Can StruxHub handle multiple project sites at once?

A: Yes, the platform supports multi-project management for contractors working across different regions or clients.

Q: Does StruxHub replace BIM or GIS?

A: No—it complements them, acting as the coordination hub that connects data from both systems to daily field operations.

StruxHub turns complex planning into seamless coordination—bridging the gap between high-level strategy and on-the-ground execution.

StruxHub

Experience the power of StruxHub today and witness firsthand how it can revolutionize your construction operations.

FAQ

What is the main difference between a Site Utilization Plan (SUP) and a Site Logistics Plan (SLP)?

The main difference between a Site Utilization Plan and a Site Logistics Plan lies in scope and timing. The SUP provides the big-picture strategy—it defines how the construction site will be organized throughout the entire project lifecycle. The SLP, by contrast, focuses on day-to-day operational details that bring that strategy to life.

Think of the SUP as the “blueprint” for the entire site. It shows where cranes, trailers, laydown zones, access roads, and temporary utilities will be placed. This plan is created during preconstruction and approved before work begins. The SLP, however, acts as the execution manual, constantly updated to reflect real-time conditions such as material deliveries, equipment movements, or site phasing.

The two plans complement one another. The SUP provides the long-term structure, while the SLP manages short-term changes within that framework. If they fall out of alignment, conflicts can arise—such as blocked access routes or overlapping work zones.

In essence, the SUP is strategic; the SLP is tactical. Both are essential for safety, efficiency, and coordination across teams. When managed properly, they ensure that planning decisions translate into smooth daily operations on even the most complex jobsites.

Who is responsible for creating and maintaining these plans?

Responsibility for these plans typically depends on project phase and role. The general contractor usually leads the development of the Site Utilization Plan during preconstruction, working alongside architects, engineers, and safety officers. The SUP often needs review and approval by owners or permitting agencies because it defines long-term logistics and site access.

Once construction begins, responsibility shifts toward field leadership. The superintendent or project logistics manager maintains the Site Logistics Plan, ensuring it reflects current site conditions. This includes daily updates for deliveries, crane positions, pedestrian routes, and staging areas. Subcontractors also play a role by providing input on access needs and material flow to avoid conflicts.

Technology has simplified collaboration. Digital tools like StruxHub allow multiple users to update site maps simultaneously. Every stakeholder—from safety managers to delivery drivers—can see the latest plan in real time. This shared visibility keeps teams synchronized and prevents mistakes caused by outdated documents.

In short, the SUP is owned by the project’s leadership during planning, and the SLP is managed collaboratively in the field. Both require continuous teamwork to keep logistics aligned throughout the project.

How often should Site Utilization and Site Logistics Plans be updated?

The Site Utilization Plan should be reviewed at major project milestones or when significant design or layout changes occur—typically every few months. Because it represents long-term strategy, it doesn’t need daily revisions, but it must evolve as the project transitions from one phase to another (for example, from foundation work to structural erection).

The Site Logistics Plan, however, should be updated far more frequently. On large or fast-paced projects, daily updates are ideal, while smaller jobs may only require weekly reviews. The SLP must always reflect the current jobsite configuration, including temporary structures, delivery gates, crane routes, and laydown zones.

Real-time technology has made this process more seamless. With platforms like StruxHub, field teams can revise layouts digitally and share updates instantly across all devices. This ensures everyone—from subcontractors to safety inspectors—is always looking at the same, most current plan.

Failing to update these documents consistently can lead to confusion, unsafe conditions, and schedule conflicts. The best-run projects treat site planning as a living process, not a one-time task.

How do these plans contribute to safety and efficiency on the jobsite?

Both the Site Utilization Plan and the Site Logistics Plan play crucial roles in maintaining a safe, efficient, and well-organized jobsite. The SUP ensures that heavy equipment, laydown areas, and access points are positioned strategically to minimize congestion and risk. The SLP ensures these arrangements are executed safely each day.

From a safety perspective, clear mapping of pedestrian routes, crane swing zones, and exclusion areas prevents accidents and keeps trades separated. For example, designating specific routes for trucks and forklifts reduces collisions, while assigning clear material storage areas prevents clutter and trip hazards.

Efficiency also improves dramatically when both plans are well-executed. Deliveries arrive on time, crews know exactly where to work, and equipment moves without conflict. Fewer surprises mean fewer delays and less downtime.

Together, these plans turn what could be a chaotic site into a coordinated system of movement and communication. They provide both structure and flexibility, allowing teams to adapt quickly while maintaining control. The result is a safer, faster, and more predictable project—something every superintendent and owner wants.

How does StruxHub help teams manage both Site Utilization and Logistics Plans more effectively?

StruxHub makes managing SUPs and SLPs easier by providing a single, unified digital platform for all site planning and logistics. Instead of juggling separate drawings and PDFs, teams can visualize the entire jobsite in one interactive map that updates in real time.

Superintendents can modify layouts directly from the field—adding new laydown zones, adjusting crane paths, or rerouting access roads—and instantly share those updates with all stakeholders. This ensures that everyone, from delivery drivers to trade foremen, works from the latest version of the plan.

StruxHub also integrates scheduling and reporting tools, allowing teams to link logistics data with daily reports, inspections, and safety documentation. This creates full visibility across planning, execution, and compliance.

By bridging the gap between the Site Utilization Plan and the Site Logistics Plan, StruxHub keeps both documents aligned, up to date, and accessible to the entire project team. It transforms static plans into living, interactive systems that drive communication, safety, and performance.

StruxHub

Discover how StruxHub can revolutionize your construction management. Contact us today!

Related Pillar Articles:

Best Guide to Construction Logistics Plans (CLPs): What Owners Want to See Before Work Starts