Why the Meta Louisiana AI Data Center Sets a New Standard for Mega Construction Project Scheduling and Site Coordination

Table of Contents:

How Did Meta Mobilize a $10B Data Center Project So Quickly?

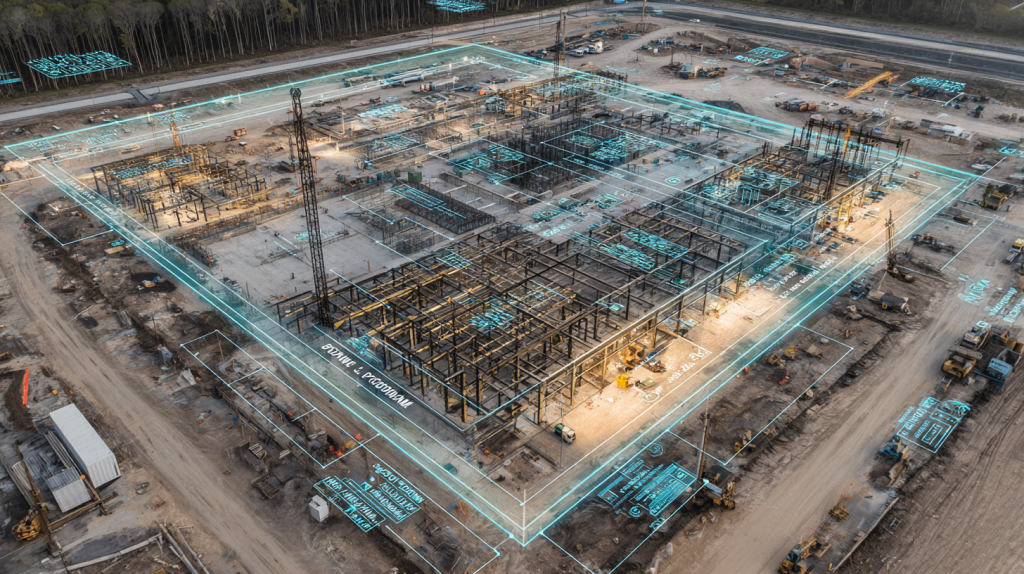

When Meta announced its $10 billion hyperscale AI campus in Richland Parish, Louisiana, the construction industry took notice—not just because of the investment size, but because of how fast the project moved from announcement to action. Within weeks, crews were onsite grading land, installing perimeter fencing, and preparing for foundational work. This speed wasn’t accidental—it was engineered.

Meta doesn’t treat project scheduling as an afterthought. Every detail—from design standardization to permitting strategy—is mapped out well before the first press release. Contractors, vendors, and utility partners are already engaged behind the scenes, with sequencing and logistics pre-negotiated. The result? Mobilization that looks more like a military operation than a traditional construction startup.

In Louisiana, Meta benefited from a prepared site (the former Franklin Farm megasite), strong state and local coordination, and a repeatable delivery model honed across other campuses. By combining these elements with modular systems and pre-aligned vendors, the company was able to start construction far faster than most public or private projects of similar scale.

Top Benefits of Meta’s Mobilization Strategy

- Eliminates lag between planning and execution

- Reduces permitting and utility delays through early collaboration

- Improves trade partner onboarding and scheduling alignment

- Builds trust with stakeholders through fast, visible progress

Best Practices for Speed-to-Site Execution

- Finalize site logistics and access before public announcements

- Use standardized building systems for rapid procurement

- Coordinate with state and utility agencies months in advance

- Pre-schedule early trades (civil, earthwork, fencing) to deploy immediately

The Richland Parish project proves that with the right prep, a $10B campus can move like a startup—and break ground in record time.

What Makes Meta’s Scheduling Model Different from Traditional Construction?

In traditional construction, scheduling is often static and linear. Teams plan months in advance but struggle to adjust in real time when delays, changes, or conflicts occur. Meta’s approach is different—it’s dynamic, zone-based, and fully integrated across trades, vendors, and commissioning teams. This model prioritizes continuous progress, not perfect plans.

At the Richland Parish site, scheduling doesn’t follow a single timeline. Instead, the project is divided into overlapping work zones, each with its own milestone targets and turnover goals. Crews are assigned by zone and task, with sequencing designed to support early commissioning and reduce trade stacking. As each zone progresses, it’s handed off—tested, inspected, and operationalized—while the rest of the site continues forward.

This modular approach improves clarity, reduces downtime, and makes it easier to isolate and resolve issues before they affect the larger schedule. Teams use digital dashboards to update progress daily, track dependencies, and shift resources proactively. The result is a jobsite that feels more like a synchronized system than a scattered collection of crews.

Top Benefits of Meta’s Scheduling Model

- Supports early turnover and phased commissioning

- Keeps field activity focused and sequenced for success

- Reduces rework and overlap between trades

- Improves forecasting accuracy with real-time data

Best Practices for Smart Scheduling

- Divide the site into clear work zones with defined milestones

- Use collaborative scheduling software for daily updates

- Review sequencing in weekly pull planning sessions

- Track progress by task, zone, and system—not just date

Meta isn’t just building fast—they’re building smarter. And their scheduling model reflects a new era of hyperscale coordination.

Why Site Coordination Must Evolve to Match Hyperscale Complexity

At a jobsite as large and complex as Meta’s Richland Parish campus, traditional coordination methods simply can’t keep up. With hundreds of workers, dozens of trade partners, and multiple scopes running in parallel, site coordination becomes a full-time discipline—and one of the most important success factors in the entire project.

Old-school whiteboards, static spreadsheets, and siloed updates don’t work when decisions must be made by the hour. Mega projects like this demand real-time communication, live field data, and digital tools that keep every stakeholder in sync. When crews don’t know where to go, what’s changed, or who’s working nearby, mistakes happen—and momentum stalls.

Meta’s approach prioritizes layered visibility. Field leaders access live jobsite maps, annotated floorplans, and zone-level task boards that update as the work progresses. Trade partners can see staging zones, access routes, and safety changes in real time. Superintendents don’t chase updates—they act on them.

This level of coordination transforms how work flows. Material delays are flagged early. Inspections are pre-scheduled by zone. Tasks are sequenced to minimize stacking and ensure every crew knows their role—without needing constant check-ins.

Top Benefits of Real-Time Site Coordination

- Reduces delays caused by confusion or outdated information

- Improves field safety through better visibility and traffic control

- Keeps trade partners accountable to zone-level progress

- Enhances productivity by aligning crews with daily changes

Best Practices for Modern Site Coordination

- Use mobile tools for real-time field communication

- Map daily logistics plans by zone and share with all crews

- Integrate RFI and inspection updates into one coordination dashboard

- Assign zone leads to manage localized task execution

To build at hyperscale, you don’t just need more people—you need better coordination. Meta’s jobsite proves exactly that.

How Meta’s Zone-Based Turnover Model Speeds Up Delivery

Meta doesn’t wait for an entire data center to be finished before moving in. Instead, it delivers in zones—completing, testing, and commissioning sections of the campus in stages. This zone-based turnover model is a cornerstone of how Meta accelerates project delivery, reduces bottlenecks, and supports early infrastructure go-live.

At the Richland Parish campus, the site is divided into manageable areas, each with its own structural, MEP, and commissioning milestones. As one zone is framed and enclosed, MEP contractors move in to install systems. Once those systems are tested, IT infrastructure can begin installation—even while other parts of the site are still in earlier phases.

This approach allows for “ribboned” scheduling, where work flows in bands across the site. It keeps trades moving, allows early detection of issues, and gives commissioning teams a head start. And it’s not just about speed—zone-based turnover improves quality too. Teams can focus on smaller areas, resolve punch items quickly, and maintain a cleaner build.

Top Benefits of Zone-Based Turnover

- Allows early commissioning of completed sections

- Improves build quality with focused execution per zone

- Reduces field congestion and trade stacking

- Accelerates time-to-operation for mission-critical systems

Best Practices for Phased Delivery

- Define turnover zones early in preconstruction

- Align scopes and inspections by zone, not just schedule

- Assign dedicated leads per zone for accountability

- Use digital tools to track punch, testing, and readiness

Zone-by-zone, Meta is turning hyperscale chaos into organized speed—and that’s redefining how large builds are delivered.

Why Standardized Scheduling Templates Reduce Risk and Rework

One of the most powerful tools in Meta’s construction strategy is its use of standardized scheduling templates. These aren’t just Gantt charts—they’re deeply detailed logistics and coordination frameworks developed across multiple campuses and refined over time. They give contractors a head start, eliminate guesswork, and reduce scheduling risk across every scope.

Standardization improves clarity. From subcontractor onboarding to trade sequencing, every partner works from a common playbook. This makes it easier to anticipate material lead times, workforce needs, and daily output expectations. And when every site uses the same baseline templates, lessons learned from one project carry directly into the next.

These templates also support better data collection. Progress can be tracked against known benchmarks, helping project managers see where teams are ahead or falling behind. In the field, this leads to more accurate forecasts, tighter crew planning, and faster decision-making.

For a hyperscale build like Richland Parish, where one missed milestone can delay commissioning, standardization is a scheduling superpower.

Top Benefits of Scheduling Templates

- Reduces startup time for new contractors and vendors

- Ensures alignment across projects with shared expectations

- Improves progress tracking with known benchmarks

- Supports continuous improvement across Meta’s build program

Best Practices for Using Standardized Schedules

- Share detailed zone schedules during trade onboarding

- Customize only where needed—stay aligned with the template

- Compare live progress against historical performance

- Refine templates after each project for long-term gains

Scheduling doesn’t have to start from scratch. Meta’s success shows that starting from the right place accelerates everything that follows.

StruxHub

Discover how StruxHub can revolutionize your construction management. Contact us today!

How Mega Project Teams Stay Aligned Without Slowing Down

On a project the size of Richland Parish, coordination meetings alone aren’t enough to keep hundreds of workers moving in sync. That’s why Meta’s teams rely on layered communication strategies and role-based accountability to keep work flowing—without dragging the project down with unnecessary overhead.

Field teams operate in self-contained units by zone or scope. Each unit has a lead responsible for daily task updates, inspection prep, and communication with adjacent teams. This decentralized structure gives teams autonomy while maintaining oversight. Everyone knows who to go to for updates—no one gets stuck in an endless approval chain.

At the same time, high-level alignment happens through shared dashboards. Project managers, superintendents, and owner reps can all view progress, issues, and risk zones in real time. This visibility reduces surprises, speeds up issue resolution, and helps identify when a small problem might snowball if not addressed quickly.

The result is a project rhythm that’s fast, fluid, and transparent—and that keeps even the biggest teams moving as one.

Top Benefits of Role-Based Field Alignment

- Reduces communication bottlenecks between trades

- Increases ownership at the zone or scope level

- Helps PMs focus on critical path and risk areas

- Speeds up daily decisions without losing visibility

Best Practices for Teamwide Alignment

- Assign trade leads and zone leads with defined responsibilities

- Use daily huddles to sync across scopes and zones

- Track tasks digitally and flag blockers early

- Review cross-trade coordination weekly to resolve conflicts

On a mega project, speed without structure leads to chaos. Meta’s system shows that structure—when done right—actually makes you faster.

How StruxHub Helps Coordinate Scheduling and Site Execution at Meta-Scale

On projects like the Meta Richland Parish campus, the schedule isn’t just a target—it’s a contract. Every delay has downstream effects across zones, trades, and commissioning timelines. StruxHub helps construction teams stay on schedule by turning planning into daily, coordinated action.

StruxHub gives field leaders and project managers a single source of truth for tasks, RFIs, inspections, and punch items—organized by zone, by system, and by schedule. Instead of juggling whiteboards or disconnected spreadsheets, superintendents use StruxHub to see what’s done, what’s ready, and what’s at risk.

On a hyperscale jobsite, the key is clarity. StruxHub gives each team lead their own view of work in progress, daily goals, and upcoming milestones. Zone leads can update status from the field. PMs can review trends. Owner reps can track turnover readiness. Everyone stays aligned—and the schedule stays real.

Meta-level construction requires Meta-level coordination. StruxHub helps turn speed into structure and high-pressure builds into smooth, predictable execution.

StruxHub

Experience the power of StruxHub today and witness firsthand how it can revolutionize your construction operations.

FAQ

What is different about Meta’s approach to construction scheduling?

Meta’s approach to construction scheduling focuses on repeatability, flexibility, and speed. Unlike traditional linear schedules, Meta breaks its projects into overlapping work zones with phased turnover. Each zone operates on its own milestone timeline, allowing portions of the facility to be commissioned and turned over while others are still under construction.

Instead of relying on static plans, Meta teams use real-time dashboards, scheduling templates, and progress tracking tools. This allows for daily updates from the field and faster adjustments when things change—whether it’s a weather delay or a material shortage. The schedule becomes a live system, not a document buried in a binder.

The company also standardizes much of its scheduling process across data center builds. That means contractors work from familiar templates, owners have clear visibility into progress, and every site benefits from lessons learned on past projects.

This model reduces rework, supports high field velocity, and keeps critical commissioning activities on track. It’s not just about building fast—it’s about building with clarity, consistency, and control.

How does Meta coordinate so many trades on a project this large?

On a project like the Richland Parish AI Campus, coordinating hundreds of workers and dozens of vendors requires a layered communication strategy and clearly defined roles. Meta uses zone-based field leadership, where each trade or phase has its own lead responsible for daily updates, inspections, and issue resolution.

Each zone or trade group reports into a broader coordination structure. Daily huddles, weekly pull planning, and real-time tracking dashboards keep all stakeholders aligned—from superintendents to safety leads to commissioning teams. Everyone knows their scope, their sequence, and their dependencies.

Technology plays a big role too. Meta and its contractors rely on digital platforms to track punch items, RFIs, inspections, and schedule milestones by zone. This helps reduce miscommunication, ensures teams don’t overlap or duplicate work, and gives the office full visibility into field progress.

By breaking the site into self-managed zones and supporting them with digital oversight, Meta creates a jobsite rhythm that feels fast—but still highly organized.

Why is phased turnover so important on hyperscale projects?

Phased turnover allows hyperscale owners like Meta to begin operating parts of a facility while construction continues in other areas. Rather than waiting for the entire site to be completed, project teams sequence the work into zones—each with its own buildout, inspection, and commissioning timeline.

This strategy delivers several benefits. First, it accelerates revenue-generating activities like server installation or infrastructure go-live. Second, it gives commissioning teams more time to test and verify critical systems in smaller chunks. And third, it spreads out risk—issues in one zone don’t halt the entire project.

On the Richland Parish campus, phased turnover will allow IT teams to start integrating hardware while construction wraps up in other areas. This helps Meta meet demand faster and reduces schedule pressure in the final months of the build.

For contractors, phased turnover means more detailed planning, tighter QA/QC, and ongoing coordination with owners. But when done well, it improves outcomes for everyone.

What makes Meta’s construction playbook repeatable across different sites?

Meta’s construction playbook is built around standardized systems—design templates, scheduling structures, material specifications, and even trade partner engagement strategies. These elements are refined across projects and then reused to speed up future builds.

This repeatable model reduces startup time for new campuses, minimizes risk, and improves collaboration with subcontractors who have worked on prior Meta sites. It also ensures quality and performance stay consistent—no matter where the project is located.

Each new site, like Richland Parish, benefits from the lessons learned at the previous one. Scheduling templates, commissioning checklists, and procurement workflows all get sharper with every iteration.

This model helps Meta scale its infrastructure faster than competitors—and gives construction teams a clear, proven structure to follow. For contractors, it means less guessing and more executing.

How can construction teams prepare to work on mega projects like Meta’s?

Construction teams aiming to work on mega projects like Meta’s need to focus on three things: systems, speed, and collaboration.

Systems: Adopt digital tools for field reporting, scheduling, RFIs, inspections, and daily logs. Teams that can operate within a real-time, centralized environment will always outperform those stuck on spreadsheets.

Speed: Mega projects move fast. Trade partners must be able to plan, mobilize, and adjust without delay. This requires proactive planning, skilled labor, and leadership that’s comfortable making decisions quickly.

Collaboration: Mega builds are a team sport. No single contractor controls the whole picture. Success depends on how well teams coordinate their work, flag issues, and keep progress moving across scopes.

Contractors should also familiarize themselves with zone-based scheduling, modular systems, and phased commissioning. These methods are becoming standard on hyperscale builds—and teams who can adapt will win the most valuable work in the years ahead.

StruxHub

Discover how StruxHub can revolutionize your construction management. Contact us today!

Pillar Articles Links:

Best Guide to Construction Logistics Plans (CLPs): What Owners Want to See Before Work Starts

Best Construction Scheduling Software for General Contractors and Superintendents